Dispensing needles, sometimes referred to as dispensing tips or dispensing nozzles, are essential tools in various industries where precise and controlled dispensing of liquids, adhesives, or other materials is crucial. These seemingly simple devices play a pivotal role in ensuring accuracy and efficiency across a wide range of applications. In this blog, we will explore what dispensing needles are, how they work, their types, and the critical roles they play in different industries.

Understanding Dispensing Needles

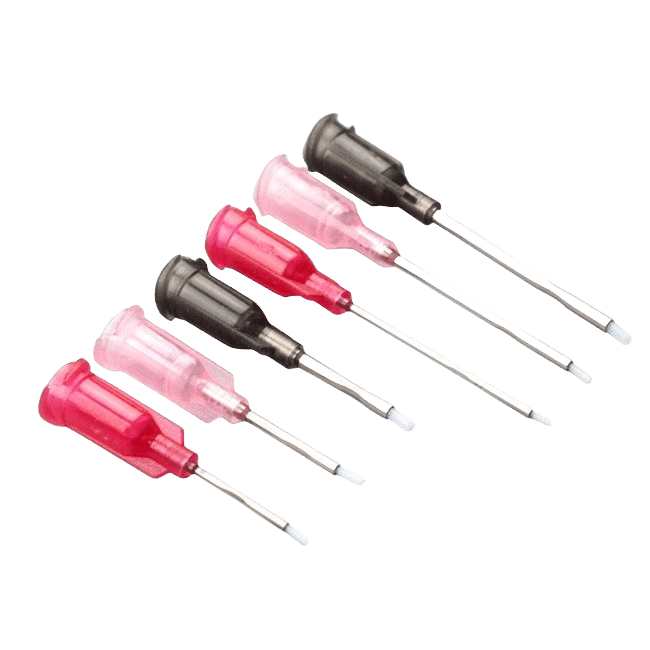

The dispensing needle is a specialized tool designed to deliver controlled amounts of a substance, typically a liquid or adhesive, to a specific location with accuracy. These needles are engineered with precision and come in various shapes, sizes, and materials to cater to different dispensing requirements. Whether in manufacturing processes, medical procedures, or crafting, dispensing needles provide the necessary control over the flow and placement of substances.

Types of Dispensing Needles

Dispensing needles come in a variety of types, each tailored to specific applications:

Blunt-End Needles:

These Blunt-End needles have a flat, blunt tip, which makes them ideal for dispensing thicker substances like adhesives and pastes. The blunt design minimizes clogging and allows for precise placement of materials.

Tapered Needles:

Tapered needles feature a gradually narrowing tip, making them suitable for dispensing liquids with varying viscosities. They facilitate smooth and controlled flow and are commonly used in medical and pharmaceutical applications.

Precision Needles:

Precision needles are extremely fine and designed for applications requiring the utmost accuracy, such as microdot dispensing of adhesives in electronics manufacturing.

Flexible Needles:

These flexible needles are made from flexible materials like plastic or silicone, enabling them to bend and conform to the contours of the workpiece. They find use in the food industry for tasks like applying icing and glazes.

PTFE-lined Needles:

PTFE-lined dispensing tips are commonly used in various industries, including pharmaceuticals, electronics manufacturing (for precise dispensing of solder paste and adhesives), and chemical processing. They are especially valuable in applications where maintaining the purity and integrity of the dispensed material is paramount.

Applications of Dispensing Needles

Dispensing needles serve a diverse range of industries and applications, including:

-

Electronics:

Electronics manufacturers use dispensing needles for applying solder pastes, adhesives, and conformal coatings during printed circuit board (PCB) assembly.

-

Automotive:

Automotive applications include applying sealants, adhesives, and lubricants in various assembly processes to ensure product reliability.

-

Medical Devices:

Medical device manufacturers rely on dispensing needles for tasks such as bonding components, encapsulating electronics, and applying medical-grade adhesives.

-

Aerospace:

In the aerospace industry, dispensing needles are used for sealing fuel tanks, bonding composite materials, and applying coatings to critical components.

-

Cosmetics:

Cosmetic manufacturers rely on these needles for the precise dispensing of creams, lotions, and other skincare products.

Why Dispensing Needles are Essential

The significance of dispensing needles lies in their ability to provide accurate, repeatable, and controlled dispensing. This precision leads to cost savings, improved product quality, and increased efficiency. Without dispensing needles, industries would face challenges such as product defects, wasted materials, and compromised safety. These needles are not merely tools; they are critical components that contribute to the success of countless products and processes.

Conclusion

Dispensing needles, with their various types and applications, are indispensable tools in numerous industries. Their ability to ensure controlled and accurate substance dispensing plays a pivotal role in maintaining product quality and efficiency. Whether you are involved in manufacturing, electronics, or creative endeavors, understanding the significance of dispensing needles can help you achieve superior results in your specific applications.