2K mixing nozzles are essential components in many industries where two-component materials such as adhesives, sealants, and coatings are used. These nozzles play a crucial role in ensuring that the two components are mixed thoroughly and consistently before application, which is critical for achieving optimal results in various applications. This article will explore the applications, design, and benefits of 2K mixing nozzles in detail.

Applications of 2K Mixing Nozzles

2K mixing nozzles find applications in various industries, including construction, automotive, aerospace, marine, and others. Here are some of the specific applications of 2K mixing nozzles in these industries:

-

Construction:

In construction, 2K mixing nozzles are used for bonding and sealing applications. They are commonly used for anchoring and doweling, crack injection, and joint sealing applications. These applications require a precise and consistent mix of two-component materials, which is achieved through the use of 2K mixing nozzles.

-

Automotive:

In the automotive industry, 2K mixing nozzles are used for bonding and sealing applications, such as body panel bonding, windshield bonding, and seam sealing. These applications require high strength and durability, which can be achieved through the use of two-component adhesives and sealants, mixed precisely with 2K mixing nozzles.

-

Aerospace:

In the aerospace industry, 2K mixing nozzles are used for composite bonding, gap filling, and other applications that require high strength, durability, and temperature resistance. These applications are critical for ensuring the safety and reliability of aerospace components and systems.

-

Marine:

In the marine industry, 2K mixing nozzles are used for bonding and sealing applications, such as hull and deck bonding, keel joint sealing, and underwater repairs. These applications require high strength and durability, as well as resistance to water, salt, and other harsh marine environments.

Design of 2K Mixing Nozzles

2K mixing nozzles come in various designs, depending on the specific application and material being used. However, most 2K mixing nozzles share some common design features, such as:

-

Static mixing elements:

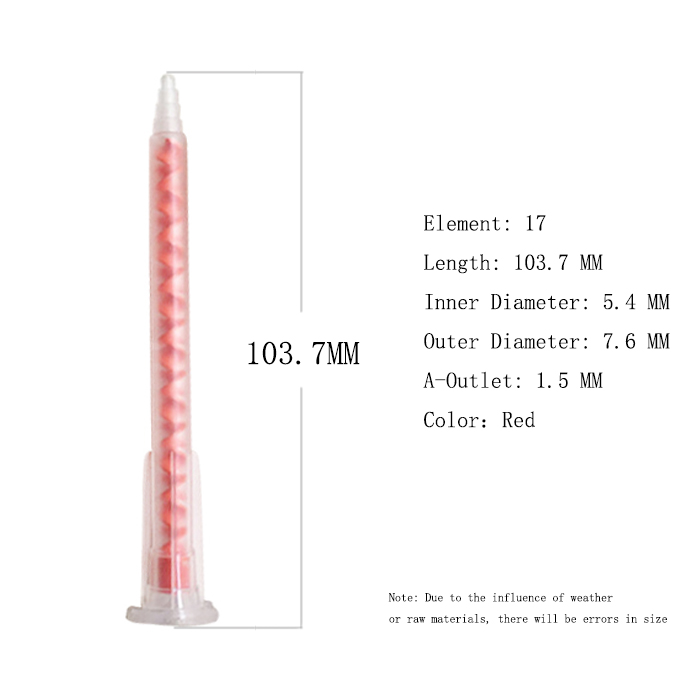

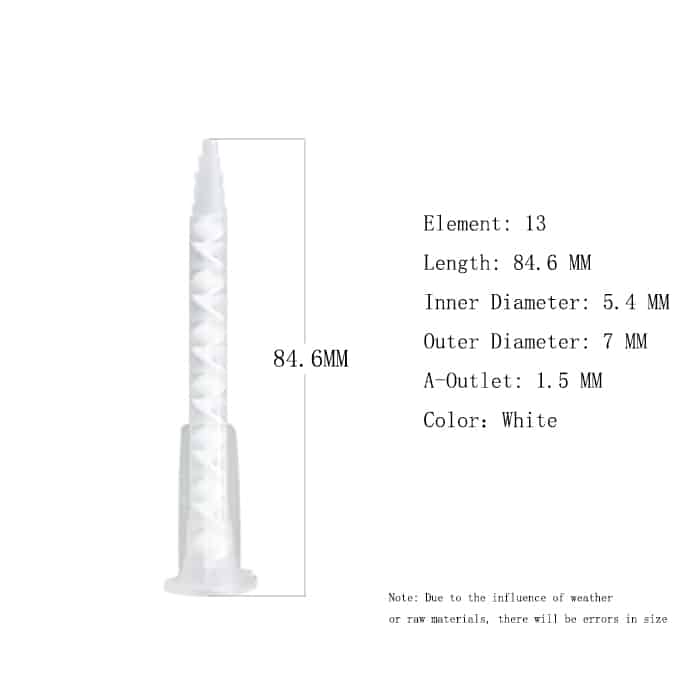

2K mixing nozzles typically have static mixing elements, which are responsible for mixing the two components of the material. These elements can be helical, straight, or other shapes, depending on the specific design and application.

-

Nozzle housing:

2K mixing nozzles have a nozzle housing that connects to the dispensing system and holds the static mixing elements. The housing can be made of various materials, such as plastic, metal, or ceramic, depending on the specific application.

-

Inlet and outlet ports:

2K mixing nozzles have inlet and outlet ports for the two components of the material. These ports can be of various sizes and shapes, depending on the specific design and application.

-

Retention nut:

2K mixing nozzles typically have a retention nut that holds the nozzle housing in place and ensures a secure connection to the dispensing system.

Benefits of 2K Mixing Nozzles

2K mixing nozzles offer several benefits over other mixing methods, such as manual mixing or mechanical mixing. Some of the benefits of 2K mixing nozzles are:

-

Precise and consistent mixing:

2K mixing nozzles ensure a precise and consistent mix of the two components of the material.

-

Reduced waste:

2K mixing nozzles help reduce waste by ensuring that only the required amount of material is dispensed and mixed, without any excess.

-

Improved quality and performance:

2K mixing nozzles ensure a thorough and consistent mix of the two components, which results in improved quality and performance of the final product or application.

-

Increased efficiency:

2K mixing nozzles can help increase efficiency by reducing the time and labor required for manual or mechanical mixing. They also allow for faster and more accurate dispensing of the material.

-

Versatility:

2K mixing nozzles can be used with various materials, including adhesives, sealants, coatings, and other two-component materials. They can also be designed for different applications and dispensing systems.

Factors to Consider when Choosing 2K Mixing Nozzles

When choosing 2K mixing nozzles for a specific application, there are several factors to consider, such as:

-

Material compatibility:

It is essential to choose a 2K mixing nozzle that is compatible with the specific material being used. Different materials have different chemical compositions, viscosities, and cure times, which can affect the performance of the 2K mixing nozzle.

-

Dispensing system compatibility:

The 2K mixing nozzle should be compatible with the dispensing system being used, whether it is a manual, pneumatic, or electric system. The nozzle should also be designed to fit the specific dispensing system’s size and shape.

-

Flow rate and mixing ratio:

The flow rate and mixing ratio of the material being dispensed should be considered when choosing a 2K mixing nozzle. The nozzle’s size and mixing elements should be selected to ensure a consistent and accurate mix of the two components.

-

Application requirements:

The specific application requirements, such as strength, flexibility, and durability, should be considered when choosing a 2K mixing nozzle. The nozzle’s design and material should be selected to meet these requirements.

-

Cost and availability:

The cost and availability of the 2K mixing nozzle should be considered when choosing a nozzle. While some high-end nozzles may offer advanced features, they may not be cost-effective for all applications.

Conclusion:

2K mixing nozzles are critical components in various industries where two-component materials such as adhesives, sealants, and coatings are used. These nozzles ensure a precise and consistent mix of the two components, resulting in improved quality, performance, and efficiency. When choosing a 2K mixing nozzle, factors such as material compatibility, dispensing system compatibility, flow rate and mixing ratio, application requirements, cost, and availability should be considered. By choosing the right 2K mixing nozzle for a specific application, businesses can improve their productivity, reduce waste, and achieve better results.

All of Btektech’s mixing nozzles are suitable for two-component dispensing systems, also known as 2k dispensing systems. We have years of experience selling mixing tubes and can provide free samples for you to test, contact us now!