In the intricate world of adhesive applications, the advent of epoxy mixing nozzles has emerged as a transformative innovation. These unassuming yet powerful devices have revolutionized the process of blending and dispensing two-part epoxy adhesives, offering a spectrum of advantages that redefine the standards of precision and reliability in bonding.

Meticulous Blending Precision

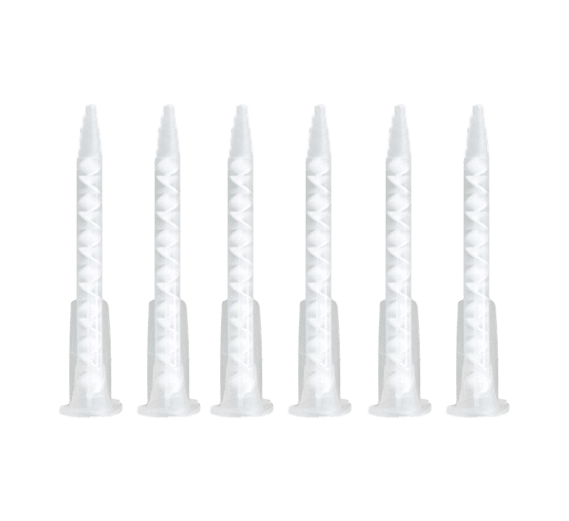

Epoxy mixing nozzles are crafted with a sophisticated dual-chambered design that orchestrates the simultaneous dispensing and thorough intermingling of resin and hardener components. The internal architecture, often featuring helical or static mixing elements, ensures an impeccable fusion of the adhesive constituents. The result is an impeccably mixed adhesive compound, eliminating inconsistencies prevalent in manual mixing methods and culminating in bonds of unparalleled uniformity and robustness.

Optimized Dispensing Efficiency

At the crux of their brilliance lies the ability of epoxy mixing nozzles to finely calibrate the dispensing ratio of adhesive components, thereby minimizing waste. Their precision-engineered design allows for precise metering, ensuring only the necessary amount is dispensed onto surfaces. This not only curtails material wastage but also simplifies the application process, amplifying efficiency and reducing clean-up efforts.

Swift Application, Uncompromised Quality

Time efficiency is a prized asset in industrial applications, and epoxy mixing nozzles are adept at optimizing this aspect. By amalgamating mixing and dispensing into a singular, seamless process, these nozzles expedite operations without compromising the integrity of bonds. In industries where rapid production cycles are imperative, this attribute proves to be a catalyst for heightened productivity.

Adaptability and Consistency

Epoxy mixing nozzles embody versatility. Available in diverse sizes and configurations, they seamlessly adapt to an array of adhesive applications and dispensing equipment. Whether employed in manual dispensing guns or automated systems, these nozzles ensure consistent performance across various adhesive viscosities, offering a dependable solution across multiple industries.

Elevated Bonding Performance

The marriage of resin and hardener through epoxy mixing nozzles ensures adhesive bonds of unparalleled strength and longevity. Their meticulous blending guarantees uniform curing, resulting in bonds that exhibit exceptional structural integrity and resilience. In industries where reliability is non-negotiable, these nozzles stand as the vanguard of superior bonding performance.

In Conclusion

Epoxy mixing nozzles epitomize a monumental leap in adhesive application technology. Their efficiency, precision, and reliability have redefined the benchmarks of industrial bonding, finding application across sectors such as automotive, aerospace, electronics, and construction. As innovation continues to progress, these nozzles promise further refinement in adhesive bonding processes, paving the way for enhanced efficiency and efficacy.

In summation, the advent of epoxy mixing nozzles signifies a paradigm shift in adhesive technology, offering professionals an unwaveringly robust and efficient means to achieve consistently strong bonds in their applications.