In the world of adhesive application, achieving the perfect mix is crucial for ensuring strong and durable bonds. Disposable mixers have emerged as a valuable tool in adhesive dispensing, offering a range of benefits that enhance efficiency and precision.

Disposable mixers are specially designed to blend adhesive components thoroughly and evenly, ensuring a consistent mixture that meets the requirements of the application. Unlike reusable mixers, which require cleaning between uses, disposable mixers can be discarded after use, eliminating the need for time-consuming cleanup and reducing the risk of cross-contamination.

In this blog series, we will delve into the world of disposable mixers for adhesive dispensing, exploring their advantages, applications, and best practices for use. Join us as we uncover the secrets behind these innovative mixers and discover how they are revolutionizing the way adhesives are applied.

Advantages of Using Disposable Mixers for Adhesive Dispensing

Disposable mixers offer several advantages over traditional reusable mixers. Here are some key benefits:

Consistent Mixing: Disposable mixers ensure a consistent and homogenous mixture of adhesives, eliminating the variability that can occur with manual mixing or reusable mixers.

Reduced Cleanup Time: Since disposable mixers are discarded after use, there is no need for time-consuming cleanup, saving both time and labor costs.

Elimination of Cross-Contamination: Disposable mixers help prevent cross-contamination between different adhesives or batches, ensuring the integrity of each adhesive mixture.

Cost-Effective: While the upfront cost of disposable mixers may be higher than reusable mixers, the savings in cleanup time and labor costs can make them a cost-effective solution in the long run.

Convenience: Disposable mixers are convenient to use, requiring no maintenance or cleaning between uses. This makes them ideal for fast-paced production environments.

Wide Range of Options: Disposable mixers are available in a variety of sizes and configurations to suit different adhesive viscosities and application requirements.

Reduced Risk of Contamination: Since disposable mixers are used once and then discarded, there is less risk of contamination from old or improperly cleaned mixers.

Improved Adhesive Performance: Properly mixed adhesives exhibit improved performance characteristics, such as increased bond strength and durability.

Applications of Disposable Mixers for Adhesive Dispensing

Disposable mixers are versatile tools that find applications across various industries. Here are some common uses:

Construction: In the construction industry, disposable mixers are used for bonding materials such as concrete, tiles, and stones. They are also used for sealing applications in buildings and infrastructure projects.

Automotive: In the automotive industry, disposable mixers are used for bonding parts such as plastic trim, panels, and mirrors. They are also used for filling and sealing applications in vehicle assembly.

Electronics: Disposable mixers are used in electronics manufacturing for bonding components such as circuit boards, sensors, and connectors. They are also used for potting and encapsulation to protect electronic components from environmental factors.

Aerospace: In the aerospace industry, disposable mixers are used for bonding and repair applications on aircraft components. They are also used in the manufacture of composite materials used in aircraft construction.

Marine: In the marine industry, disposable mixers are used for bonding and repair applications on boats and ships. They are also used for sealing applications to prevent water ingress.

DIY and Hobbyist: Disposable mixers are popular among DIY enthusiasts and hobbyists for various projects such as woodworking, model building, and crafts.

Medical: In the medical industry, disposable mixers are used for bonding and sealing applications in medical devices and equipment.

General Manufacturing: Disposable mixers are used in general manufacturing for bonding and sealing applications in various industries such as appliances, furniture, and sporting goods.

Design Features of Disposable Mixers for Efficient Adhesive Mixing

Disposable mixers are designed with specific features to ensure efficient and thorough mixing of adhesives. Here are some key design features to look for:

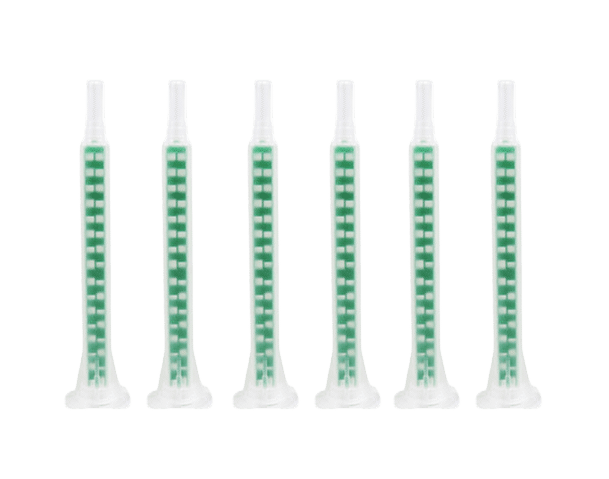

Helical Mixing Elements: Disposable mixers often feature helical mixing elements that help to create a swirling motion, ensuring thorough mixing of adhesive components.

Multiple Elements: Some disposable mixers have multiple mixing elements to further enhance mixing efficiency and ensure a homogenous mixture.

Optimized Geometry: The geometry of the disposable mixer, including the shape and size of the mixing elements, is optimized to provide the best possible mixing performance for a given adhesive.

Materials: Disposable mixers are typically made from materials that are compatible with a wide range of adhesives and are resistant to chemical reactions that may occur during mixing.

Connection Type: Disposable mixers come in various connection types to ensure compatibility with different dispensing equipment, such as syringe barrels or dispensing guns.

Length and Diameter: The length and diameter of the disposable mixer can affect the mixing performance and flow rate of the adhesive, so it’s important to choose a size that is suitable for your application.

Disposable vs. Reusable: Disposable mixers are designed for single-use and are discarded after use, while reusable mixers can be cleaned and reused multiple times. The choice between disposable and reusable mixers depends on the application requirements and frequency of use.

Compatibility with Adhesive: It’s important to ensure that the disposable mixer is compatible with the specific adhesive being used, including its viscosity and mixing ratio requirements.

How to Choose the Right Disposable Mixer for Your Adhesive Application

Choosing the right disposable mixer is crucial for achieving optimal adhesive mixing and application. Here are some factors to consider:

Adhesive Type: Consider the type of adhesive you will be using, including its viscosity, curing time, and mixing ratio requirements. Choose a disposable mixer that is compatible with these specifications.

Application Method: Determine how the adhesive will be dispensed (e.g., syringe, cartridge, or pneumatic dispenser) and select a disposable mixer that is compatible with your dispensing equipment.

Mixing Efficiency: Look for disposable mixers with efficient mixing elements (e.g., helical or static mixers) that can thoroughly blend the adhesive components in a short amount of time.

Size and Shape: Choose a disposable mixer that matches the size and shape of your dispensing equipment to ensure a proper fit and efficient mixing.

Disposable vs. Reusable: Consider whether you need a disposable mixer for single-use applications or a reusable mixer for multiple uses. Disposable mixers are convenient but can be more costly in the long run compared to reusable mixers.

Compatibility with Dispensing Equipment: Ensure that the disposable mixer is compatible with your dispensing equipment, including the connection type and size.

Cost-Effectiveness: Evaluate the cost of the disposable mixer in relation to its performance and durability to ensure that you are getting the best value for your investment.

Environmental Impact: Consider the environmental impact of using disposable mixers and explore eco-friendly alternatives if sustainability is a concern.

Disposable Mixer Compatibility:

Disposable mixers are an essential component in adhesive dispensing systems, but ensuring compatibility with both the adhesive being used and the dispensing equipment is crucial for successful application. Here’s how to ensure compatibility:

Adhesive Compatibility:

Viscosity: Choose a disposable mixer that is designed to handle the viscosity of your adhesive. Low-viscosity adhesives may require a different mixer design than high-viscosity ones.

Chemical Compatibility: Ensure that the materials used in the disposable mixer are compatible with the chemicals in your adhesive. Some adhesives may react with certain plastics or metals, affecting the adhesive properties.

Curing Time: Consider the curing time of your adhesive and choose a mixer that can mix the components quickly and efficiently to avoid premature curing.

Dispensing System Compatibility:

Connection Type: Ensure that the disposable mixer has a connection type that is compatible with your dispensing equipment. Common types include luer lock, bayonet, and threaded connections.

Size and Length: Choose a disposable mixer that is the right size and length for your dispensing equipment to ensure proper fit and efficient mixing.

Flow Rate: Consider the flow rate of your dispensing equipment and choose a disposable mixer that can handle the flow rate without causing back pressure or other issues.

Testing Compatibility:

Before using a disposable mixer with a new adhesive, it’s a good idea to test the compatibility by mixing a small batch and observing the results. Look for any issues such as incomplete mixing or premature curing.

If possible, consult with the manufacturer of the adhesive and the disposable mixer to ensure compatibility.

Proper Use and Maintenance of Disposable Mixers:

Disposable mixers are valuable tools in adhesive dispensing, but proper use and maintenance are essential to ensure their optimal performance. Here’s a guide on how to use and maintain disposable mixers:

Proper Use:

Attach Correctly: Ensure that the disposable mixer is securely attached to the dispensing equipment to prevent leaks or dislodging during use.

Prime Before Use: Before dispensing adhesive, prime the disposable mixer by dispensing a small amount of adhesive to ensure that the mixing elements are properly coated.

Mix Thoroughly: Follow the manufacturer’s instructions for mixing the adhesive components thoroughly to ensure a homogenous mixture.

Use Immediately: Once the adhesive is mixed, use it immediately to prevent it from curing inside the disposable mixer.

Maintenance:

Clean After Use: After using the disposable mixer, clean it thoroughly to remove any adhesive residue. Use a suitable solvent or cleaning solution recommended by the manufacturer.

Inspect for Damage: Regularly inspect the disposable mixer for any signs of damage, such as cracks or wear. Replace the mixer if any damage is found.

Store Properly: Store the disposable mixer in a clean and dry place when not in use to prevent contamination and damage.

Disposable vs. Reusable: Remember that disposable mixers are designed for single-use and should not be reused. Using a disposable mixer multiple times can affect its performance and the quality of the adhesive mixture.

Environmental Considerations: Dispose of used disposable mixers according to local regulations. Some mixers may be recyclable, so check with local recycling facilities for guidance.

By following these guidelines for proper use and maintenance, you can ensure that your disposable mixers perform optimally and provide reliable adhesive mixing for your applications.