Static mixing nozzle for fluid mixing

Fluid mixing is a crucial step in many industrial applications. One method of mixing is using a static mixing nozzle, which is a device that can be used to mix fluids as they pass through the nozzle. This article will give a general overview of static mixing nozzles, their construction, and their application in various industries.

What is static mixing nozzle?

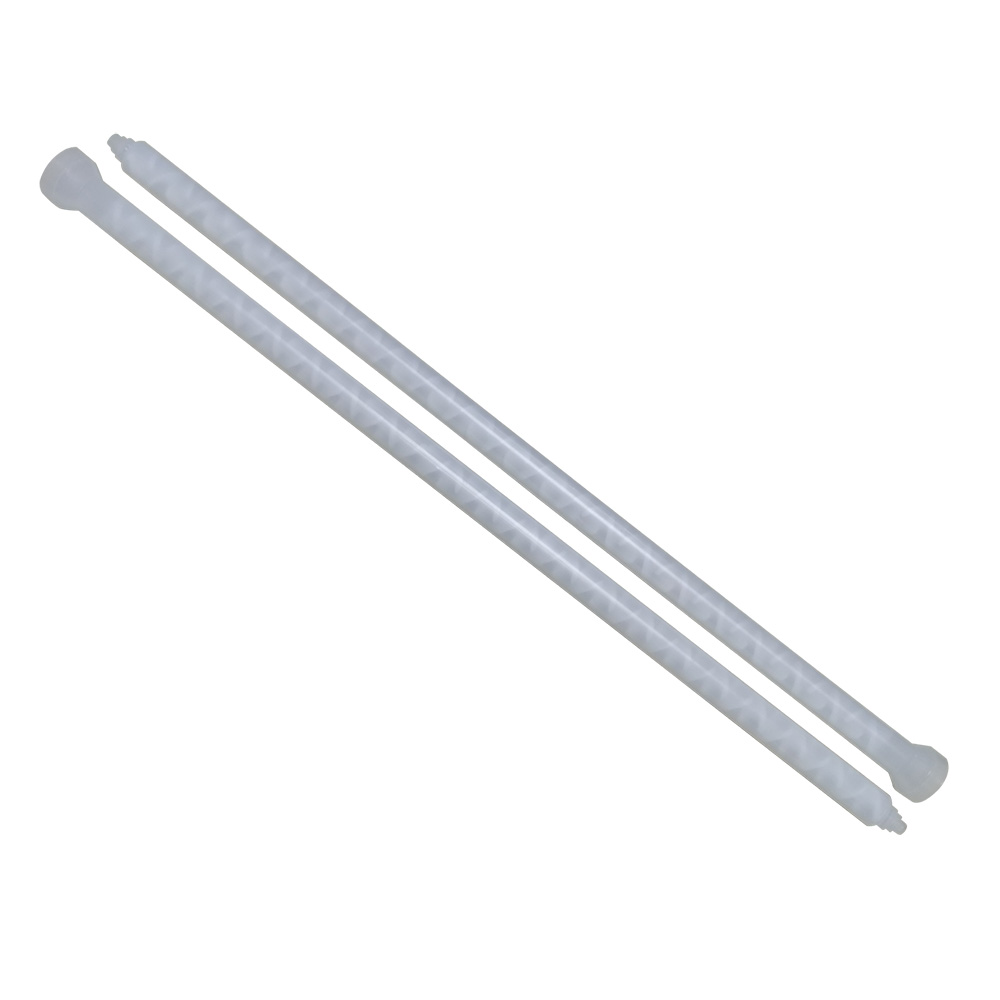

The static mixing nozzle is a device that’s usually used to mix two or more fluids as they pass through the nozzle. The nozzle is made up of a series of static mixing elements that create turbulence and eddies within the fluid flow, which leads to thorough mixing. Typically, the elements consist of alternating layers of baffles that are twisted and crossed over, the more elements it have, the better the mix will be.

Design of static mixing nozzle:

The purpose of static mixing nozzle’s design is to produce as much turbulence and mixing as possible in a confined area. Depending on the use, a static mixing nozzle’s design might change, however most static mixing nozzles are constructed of a number of twisted and crossed-over baffles that stir up the fluid flow. Depending on the intended degree of mixing and the kind of fluid being mixed, the form, size, and quantity of baffles need to change.

If the static mixing tube products on the market can not meet your needs, you can look for static mixing nozzle manufacturers to customize.

Materials of static mixing nozzle:

Depending on the purpose, a variety of materials can be used to create static mixing nozzles. The static mixing nozzles on the market are frequently made of plastic, stainless steel, and carbon steel. The choice of material will depend on factors such as chemical compatibility, pressure, temperature, and the type of fluid being mixed. If you’re not sure which kind of static mixing nozzle is suitable for your produce, you can contact us for help.

Applications of static mixing nozzles:

Static mixing nozzles are employed in a variety of industrial settings, include:

-

Chemical processing:

To combine ingredients and produce homogeneous blends, static mixing nozzles are employed in the manufacture of chemicals. They are applicable to procedures including polymerization, emulsion, and blending.

-

Water treatment:

Static mixing nozzles are used in water treatment applications to mix chemicals and disinfectants into the water supply. They can be used to mix chlorine, fluoride, and other chemicals into the water.

-

Food and beverage processing:

In the food and beverage sector, static mixing nozzles are used to blend components uniformly. They are applicable to procedures including flavoring, emulsifying, and blending.

-

Pharmaceutical manufacturing:

Static mixing nozzles are used in the pharmaceutical industry to mix ingredients and create homogeneous blends. They can be used in processes such as granulation, drying, and blending.

Advantages of static mixing nozzles:

Static mixing nozzles offer several advantages over other methods of mixing, including:

-

Thorough mixing:

The turbulence and eddies produced by static mixing nozzles in the fluid flow result in thorough mixing.

-

Reduced waste:

Static mixing nozzles can be used to mix small amounts of fluids, which reduces waste.

-

Compact design:

Because of its ability to produce as much mixing as possible in a compact area, static mixing nozzles are perfect for use in applications where available space is at a premium.

-

Simple installation:

Static mixing nozzles are simple to adapt into existing systems.

Conclusion:

Static mixing nozzles are a versatile and effective method of mixing fluids in a wide range of industrial applications. They are a desirable solution for many businesses because of their small size, simplicity of installation, and capacity for complete mixing. Engineers and operators can select the ideal mixing solution for their unique demands by becoming familiar with the design and use of static mixing nozzles.