Epoxy mixing nozzles are critical components in various industries, and China has emerged as a prominent hub for manufacturing these precision tools. In this blog post, we will explore the advantages and considerations of sourcing epoxy mixing nozzles from factories in China. Whether you’re a business owner looking for cost-effective solutions or a procurement professional seeking reliable suppliers, this guide will provide valuable insights into the process.

Advantages of Sourcing from China

1. Cost-Effective Production

Chinese factories often offer competitive pricing due to lower production costs. This can lead to significant savings, especially for bulk purchases, making it an attractive option for businesses looking to optimize their budgets.

2. Wide Range of Options

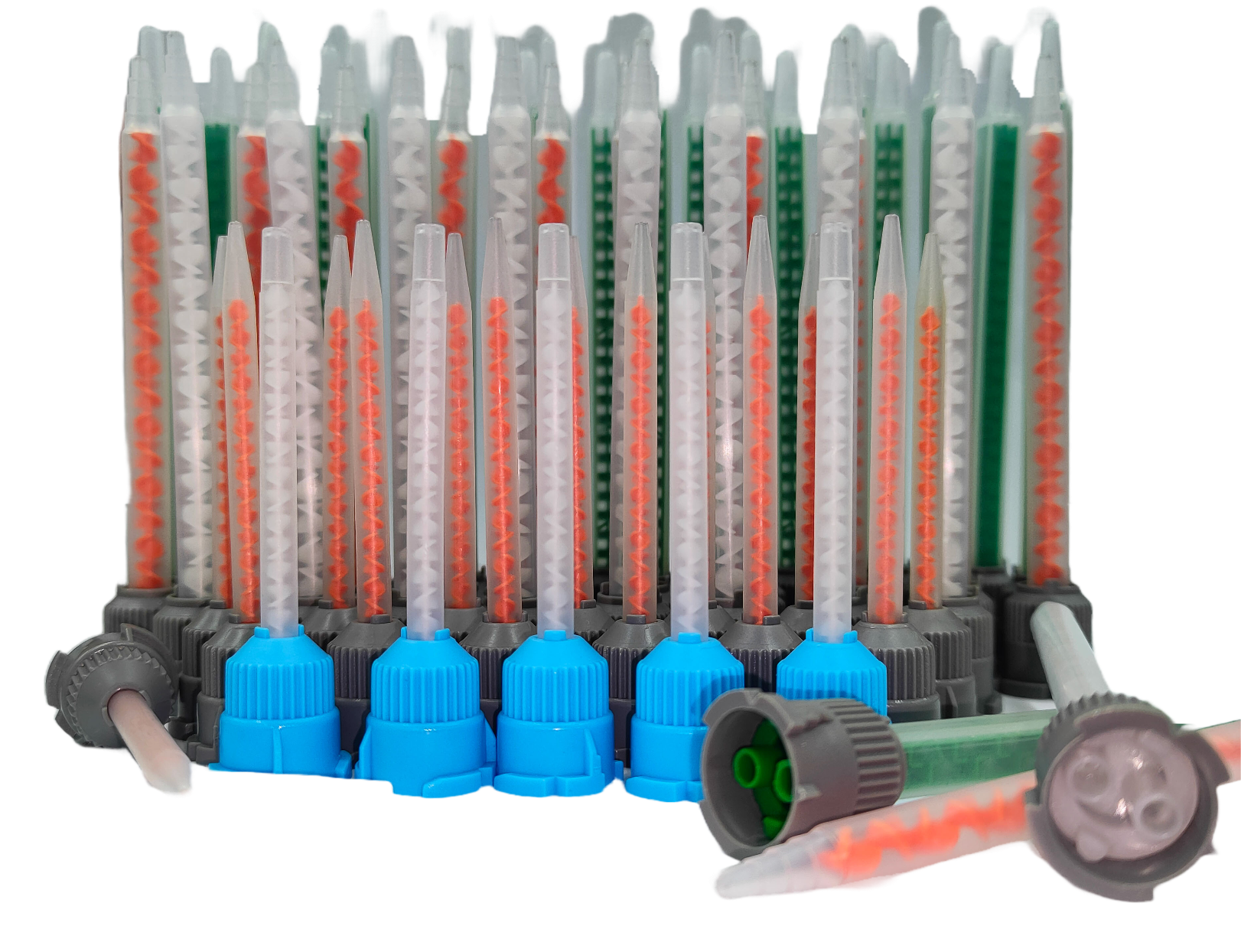

China boasts a vast network of manufacturers specializing in epoxy mixing nozzles. This diversity provides you with a wide range of options in terms of nozzle types, sizes, and materials, allowing you to find the perfect fit for your specific needs.

3. High-Quality Manufacturing

Many Chinese factories are equipped with advanced machinery and adhere to international quality standards. This ensures that you can source high-quality epoxy mixing nozzles that meet or exceed industry requirements.

4. Manufacturing Expertise

China has accumulated decades of experience in manufacturing various products, including precision tools like epoxy mixing nozzles. This expertise translates into well-crafted, reliable products.

Considerations When Sourcing from China

1. Supplier Verification

It’s crucial to thoroughly vet potential suppliers in China. Look for reputable manufacturers with a track record of producing quality epoxy mixing nozzles and providing reliable customer service.

2. Quality Assurance

Request samples and verify the quality of the epoxy mixing nozzles before placing bulk orders. Make sure the supplier can meet your specific quality standards and requirements.

3. Communication

Effective communication is key to a successful partnership. Ensure that you can communicate with the supplier clearly and efficiently, addressing any concerns or customization requests.

4. Shipping and Import Regulations

Familiarize yourself with shipping options and import regulations. Understand the shipping costs, lead times, and any import duties or taxes associated with sourcing from China.

Conclusion

Sourcing epoxy mixing nozzles from factories in China can be a strategic decision for businesses and professionals seeking cost-effective, high-quality solutions. By leveraging the advantages of competitive pricing, a wide range of options, and manufacturing expertise, you can find reliable suppliers to meet your epoxy mixing nozzle needs. However, due diligence in supplier verification, quality assurance, communication, and understanding shipping logistics is essential for a successful sourcing experience.

Btektech is a professional manufacturer of epoxy mixing nozzles, we are able to provide various types of epoxy mixing nozzles, such as square mixing nozzles, 50ml mixing nozzles and dynamic mixing nozzles. If you have special needs for mixing nozzle length, parts, then Btektech also provides customized service, so that you can solve the urgent needs of mixing nozzles.