Resin mixer nozzles and epoxy mixing nozzles are common terms used in the world of adhesives and coatings. While they may sound similar, they refer to slightly different products. Let’s explore the differences and clarify what each term means.

Resin Mixer Nozzle:

The resin mixer nozzle is a device used in dual-component adhesive systems, where two separate materials are mixed together to create a chemical reaction that results in a hardened adhesive or coating. These systems typically consist of a resin (Part A) and a hardener (Part B), which need to be thoroughly mixed in a specific ratio to achieve optimal curing and performance.

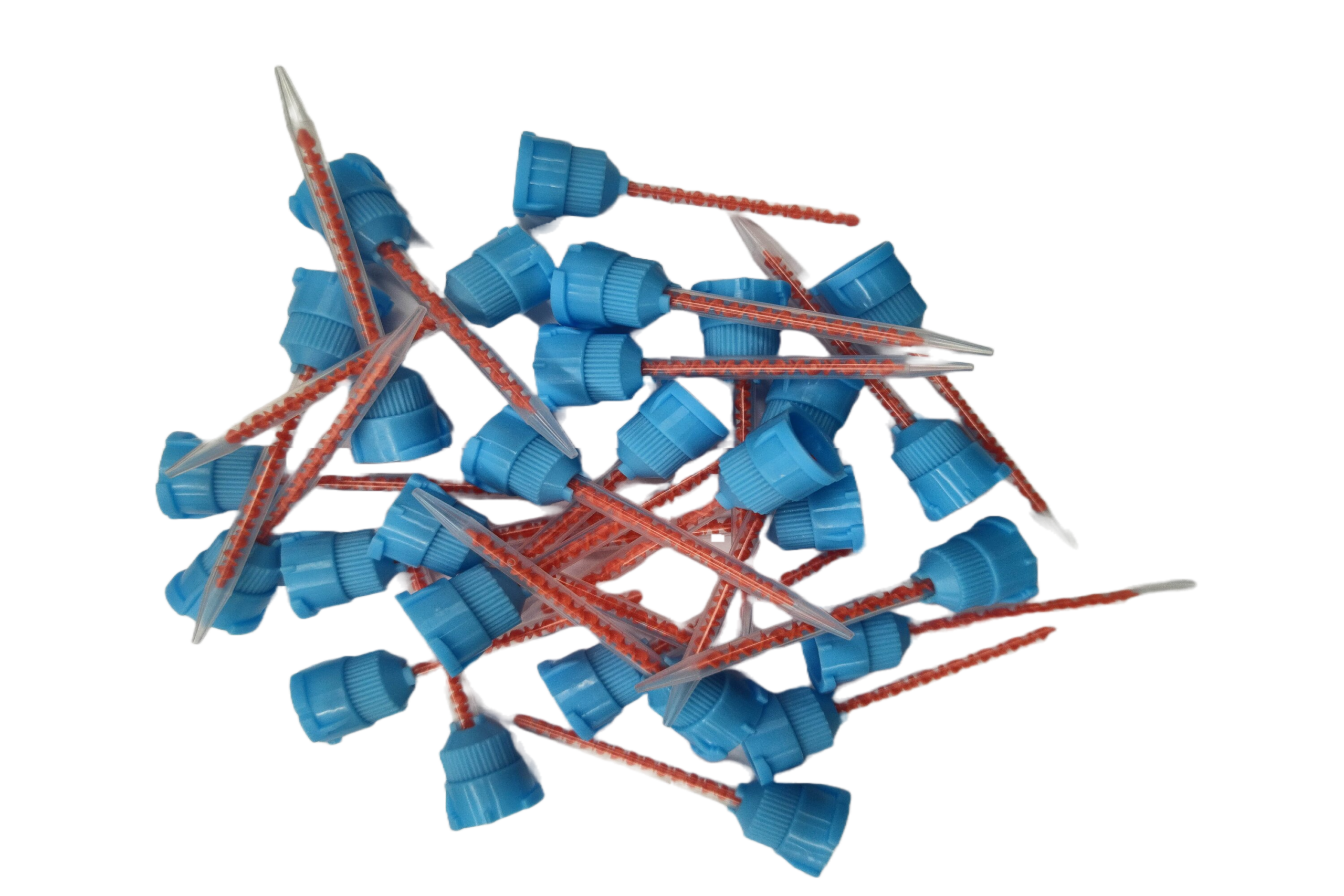

The resin mixer nozzle is a key component of a dispensing system designed to mix the resin and hardener precisely. It is usually made of plastic and features a static mixing element inside. This element consists of a series of helical or spiral-shaped elements that combine the resin and hardener as they flow through the nozzle.

When the resin and hardener components are forced through the mixer nozzle, the mixing elements create turbulence and shearing action, ensuring thorough blending of the two materials. This process is essential to achieve a homogenous mixture, which is crucial for the adhesive or coating to perform as intended.

Epoxy Mixing Nozzle:

On the other hand, an epoxy mixing nozzle is a specific type of resin mixer nozzle that is commonly used in epoxy adhesive applications. Epoxy adhesives are versatile and widely used in various industries due to their excellent bonding strength and durability. These adhesives consist of an epoxy resin and a hardener, which need to be mixed together just like other dual-component systems.

Epoxy mixing nozzles are similar to resin mixer nozzles in terms of their function. They feature the same helical or spiral-shaped mixing elements inside, which thoroughly blend the epoxy resin and hardener as they pass through the nozzle. The primary difference lies in the name, as the term “epoxy mixing nozzle” specifically refers to a mixer nozzle used for epoxy-based adhesives.

It’s important to note that while epoxy mixing nozzles are designed for epoxy adhesives, they can also be used with other dual-component resin systems that require thorough mixing. The key is to ensure compatibility between the nozzle and the materials being dispensed to achieve optimal results.

Conclusion

In summary, the terms “resin mixer nozzle” and “epoxy mixing nozzle” are related but not interchangeable. The resin mixer nozzle is a general term used for nozzles used in dual-component adhesive systems, whereas an epoxy mixing nozzle is a specific type of resin mixer nozzle designed for epoxy-based adhesives. Both types of nozzles serve the same purpose of mixing two components to achieve a homogenous mixture. So, if you’re working with epoxy adhesives, using an epoxy mixing nozzle would be the appropriate choice to ensure proper mixing and bonding performance.