Adhesive mixing nozzles are essential tools used in various industries to ensure accurate and efficient application of adhesives. Understanding the fundamentals of adhesive mixing nozzles is crucial for achieving optimal results in your adhesive processes. In this blog, we will explore the ins and outs of adhesive mixing nozzles, including their purpose, types, benefits, and best practices for their use.

What are Adhesive Mixing Nozzles?

Definition and Function: Adhesive mixing nozzles are devices that facilitate the mixing of two or more components of an adhesive, typically a resin and a hardener, at the point of application. They ensure thorough mixing and homogeneity of the adhesive, leading to consistent performance and bonding strength.

Types of Adhesive Mixing Nozzles:

-

Static Mixers:

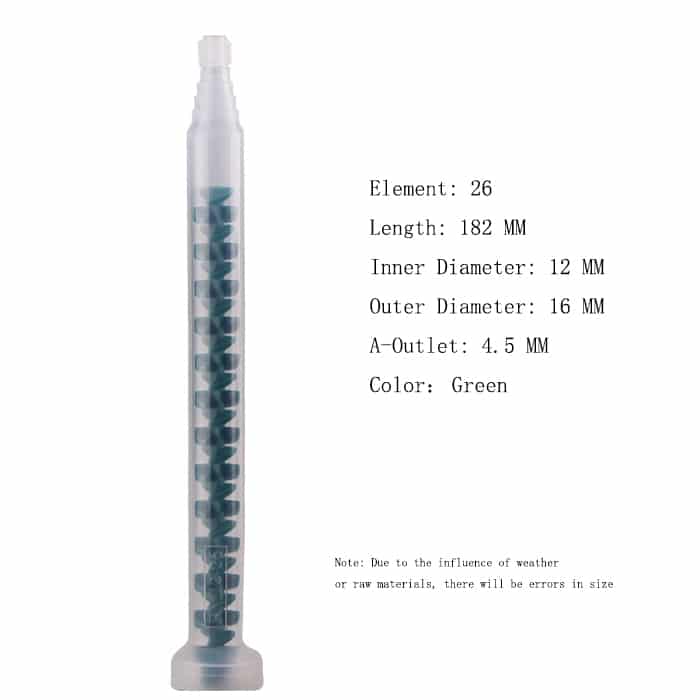

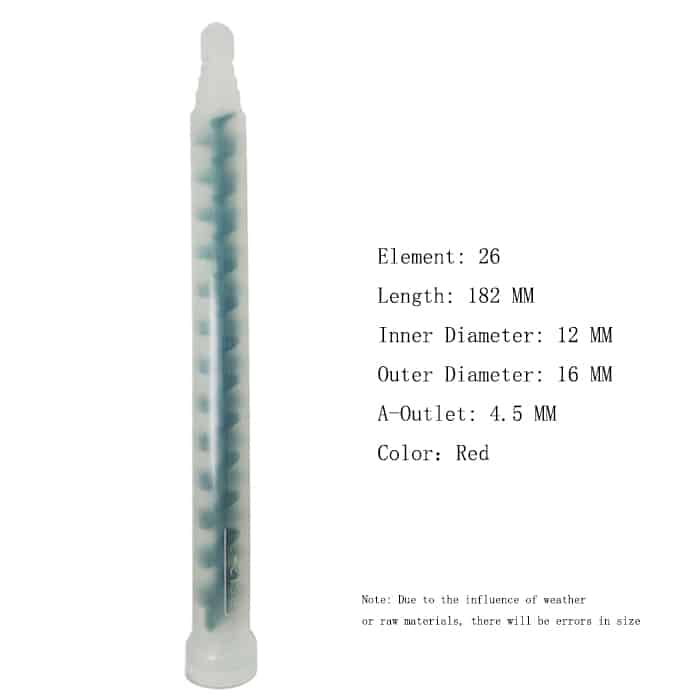

Static mixers consist of a series of elements that redirect and divide the flow of the adhesive, promoting mixing as it passes through the nozzle.

-

Dynamic Mixers:

Dynamic mixers utilize moving parts or elements to create turbulence and enhance mixing during the adhesive dispensing process.

-

Specialty Nozzles:

Specialty nozzles are designed for specific applications, such as high-viscosity adhesives, dual-component adhesives, or precise ratio control.

Benefits of Adhesive Mixing Nozzles:

-

Consistent Mixing:

Adhesive mixing nozzles ensure consistent and uniform mixing, minimizing variations in adhesive properties and improving bond strength.

-

Waste Reduction:

By mixing the adhesive components at the point of application, adhesive mixing nozzles help minimize waste and reduce material costs.

-

Increased Efficiency:

These nozzles streamline the adhesive application process, enhancing productivity and reducing assembly time.

-

Improved Bond Quality:

Thorough mixing provided by the nozzles results in better adhesive wetting and bonding, leading to stronger and more reliable bonds.

Best Practices for Using Adhesive Mixing Nozzles:

-

Proper Nozzle Selection:

Choose a mixing nozzle that is compatible with your adhesive type, viscosity, and dispensing equipment.

-

Nozzle Preparation:

Ensure that the nozzle is clean and free from any residual adhesive before attaching it to the dispensing system.

-

Mixing Ratio Control:

Follow the recommended mixing ratio for your adhesive, and verify that the nozzle provides accurate and consistent ratio control.

-

Dispensing Technique:

Maintain a consistent and controlled dispensing technique to ensure proper mixing and avoid air entrapment.

-

Nozzle Cleaning and Maintenance:

Clean the nozzle regularly to prevent clogging and maintain optimal performance. Refer to manufacturer guidelines for specific cleaning procedures.

Conclusion:

Adhesive mixing nozzles play a critical role in achieving efficient and high-quality adhesive applications. Understanding their purpose, types, benefits, and best practices for their use is essential for maximizing the performance of your adhesive processes. By selecting the appropriate nozzle, following proper mixing procedures, and maintaining regular cleaning and maintenance, you can achieve consistent results and robust bonds in your adhesive applications.

Btektech is a manufacturer of adhesive mixing nozzles from China, they offer different types of adhesive mixing nozzles and support customization services.

Btektech has been supplying adhesive mixing nozzles all over the world for more than 10 years and supplying millions of adhesive mixing nozzles all over the world every year.

This company is known for their excellent prices and high quality products.