Epoxy resin is a versatile and widely used material in various industries, known for its strength, durability, and adhesive properties. To achieve successful results, it is crucial to understand the proper mixing techniques when combining epoxy resin and hardener. In this article, we will introduce epoxy resin and hardener, explore different mixing methods, and discuss the advantages and disadvantages of each approach.

Epoxy Resin and Hardener:

Epoxy resin is a two-part material consisting of a resin and a hardener. The resin acts as the base component, providing the bulk of the material, while the hardener initiates the chemical reaction that leads to curing. When combined in the correct ratio, epoxy resin and hardener create a strong and durable substance with various applications.

Different Ways to Mix Epoxy Resin and Hardener:

-

Use of Epoxy Mixing Nozzle:

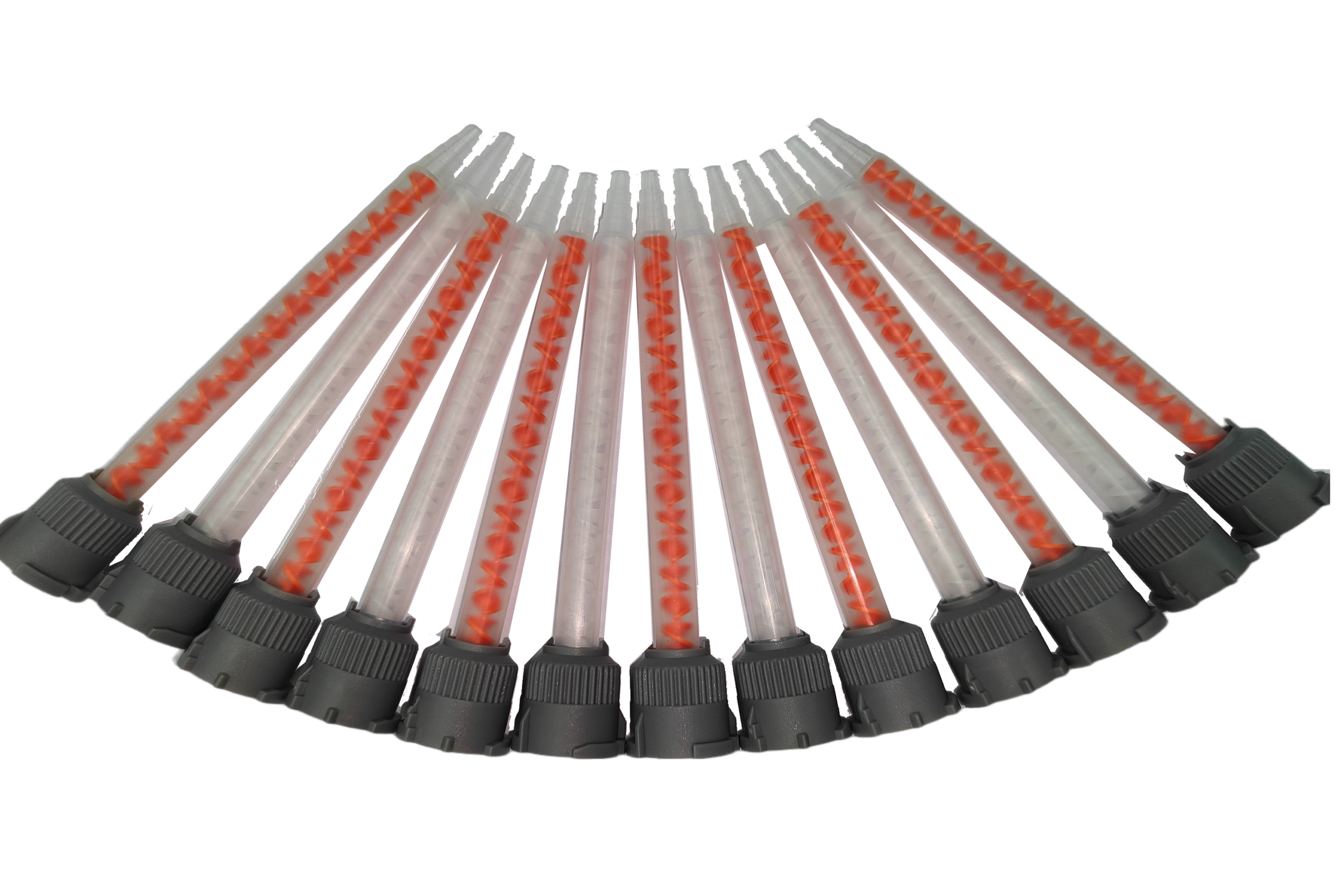

Epoxy mixing nozzles are specifically designed for combining epoxy resin and hardener. These nozzles have two separate channels that merge into a mixing chamber, ensuring precise blending. Follow these steps when using epoxy mixing nozzles:

Advantages:

- Provides an accurate mixing ratio without the need for manual measurement.

- Promotes efficient and homogeneous mixing, resulting in a uniform blend.

- Minimizes the incorporation of air bubbles into the mixture.

- Convenient and time-saving, reducing the preparation time for epoxy application.

Disadvantages:

- Requires specific epoxy mixing nozzles that may not be readily available.

- Additional cost compared to other mixing methods.

-

Hand Stirring:

Hand stirring is a common and accessible method for mixing epoxy resin and hardener. To use this technique:

Advantages:

- Cost-effective and readily available.

- Allows for better control over the mixing process.

- Suitable for small-scale projects or when working with small amounts of epoxy.

Disadvantages:

- Requires more effort and time compared to other mixing methods.

- Difficult to achieve thorough and consistent mixing, especially with larger volumes of epoxy.

-

Use of Epoxy Mixing Paddle:

Using an epoxy mixing paddle, which can be attached to a power drill, offers a more efficient and consistent mixing process. Here’s how to use it:

Advantages:

- Enables faster and more thorough mixing compared to hand stirring.

- Ensures a consistent blend, reducing the risk of unmixed portions.

- Ideal for larger-scale projects or when mixing larger volumes of epoxy.

Disadvantages:

- Requires a power drill and epoxy mixing paddle attachment.

- May introduce air bubbles into the mixture if not used carefully.

-

Other Ways:

There are additional methods for mixing epoxy resin and hardener, depending on the specific project requirements and available equipment. These include using vacuum degassing equipment to remove air bubbles or utilizing specialized equipment like a resin mixer machine.

Advantages and disadvantages of these methods can vary widely and depend on the specific equipment used.

Conclusion:

When working with epoxy resin and hardener, achieving a well-mixed and homogeneous blend is crucial for optimal results. Hand stirring, using an epoxy mixing paddle, or employing an epoxy mixing nozzle are common methods to achieve this. Each method offers distinct advantages and disadvantages in terms of control, efficiency, and air bubble reduction.

Consider the scale of your project, available equipment, and desired outcome when choosing a mixing technique. By mastering the art of epoxy resin and hardener mixing, you can confidently tackle your projects and achieve the desired strength, durability, and aesthetics in your epoxy-based creations.