Disposable static mixing nozzles have become a popular choice for industrial applications due to their ability to improve mixing efficiency, reduce waste, and minimize maintenance costs. However, it’s important to understand how to properly use and maintain these nozzles to achieve optimal results. In this article, we will discuss how to maximize efficiency and cost savings with disposable static mixing nozzles.

Section 1: Choosing the Right Nozzle

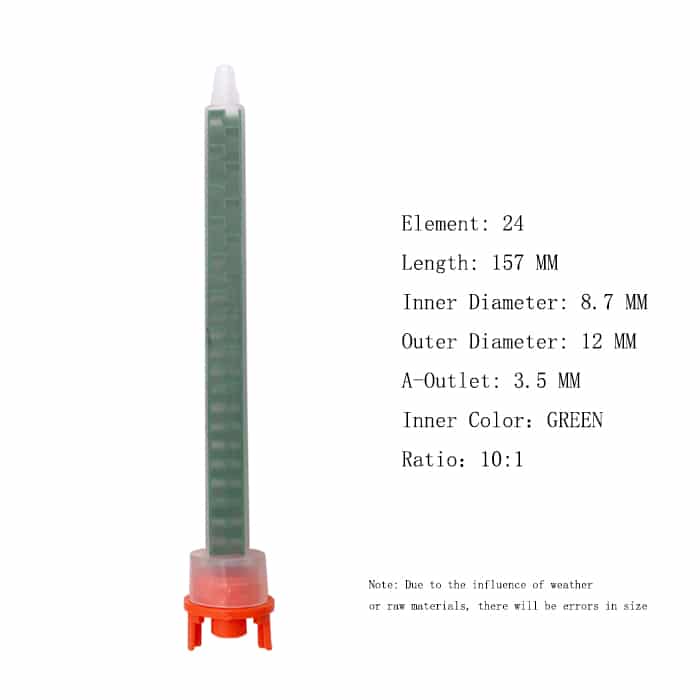

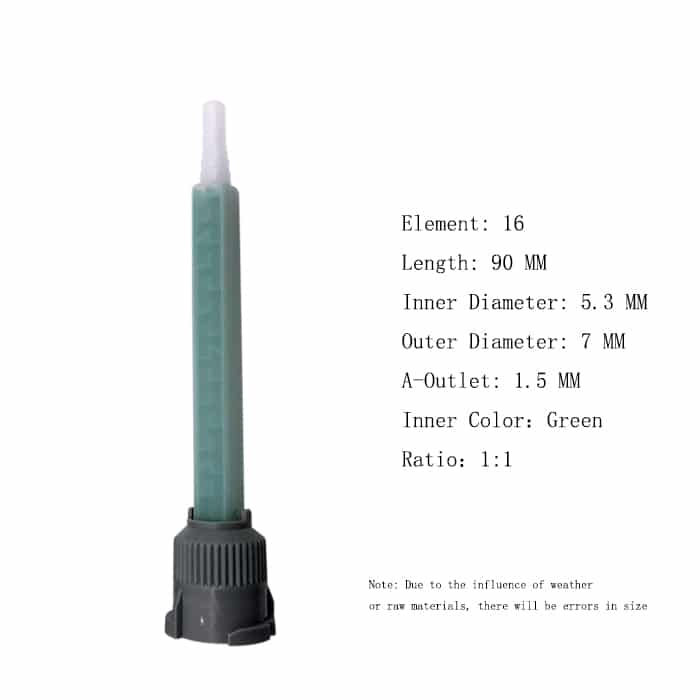

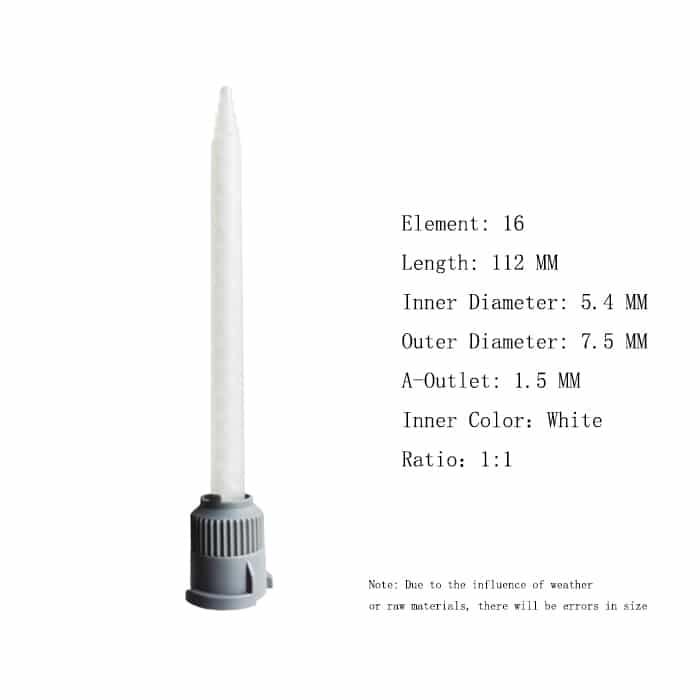

The first step in maximizing efficiency with disposable static mixing nozzles is to choose the right nozzle for your application. The nozzle size and geometry will depend on the material being dispensed, the desired mixing ratio, and the dispensing equipment being used. Some tips for selecting the right nozzle include:

- Consider the viscosity and flow rate of the materials being dispensed

- Choose a nozzle that is compatible with your dispensing equipment

- Ensure that the nozzle is designed for the desired mixing ratio

- Consider the size of the mixing element and the overall length of the nozzle for optimal mixing

Section 2: Proper Material Preparation

Proper material preparation is crucial for achieving optimal mixing performance with disposable static mixing nozzles. The materials should be prepared according to the manufacturer’s instructions, which may include mixing, degassing, and filtering. Some additional tips for material preparation include:

- Store the materials at the recommended temperature and humidity

- Use high-quality materials to minimize impurities

- Mix the materials thoroughly before dispensing to ensure consistent performance

- Use a compatible primer or surface treatment if necessary

Section 3: Dispensing Techniques

Dispensing techniques play a significant role in achieving optimal efficiency with disposable static mixing nozzles. Some tips for improving dispensing efficiency include:

- Use a dispensing equipment that is compatible with the nozzle and materials being dispensed

- Dispense the materials at the recommended flow rate and pressure

- Keep the nozzle perpendicular to the surface being dispensed for optimal coverage

- Clean the nozzle between each dispensing session to prevent clogging and ensure consistent performance

Section 4: Maintenance and Storage

Proper maintenance and storage are essential for extending the lifespan of disposable static mixing nozzles and achieving optimal performance. Some tips for maintenance and storage include:

- Replace the nozzle after each use to prevent contamination and ensure consistent performance

- Store the nozzles in a cool, dry place away from direct sunlight

- Check the expiration date before using the nozzle

- Clean the dispensing equipment regularly to prevent clogging and ensure consistent performance

Conclusion:

Disposable static mixing nozzles offer many benefits over traditional mixing methods, including improved mixing efficiency, reduced waste, and cost savings. By choosing the right nozzle, properly preparing the material, using the correct dispensing techniques, and maintaining the nozzles and dispensing equipment, you can maximize the benefits of disposable static mixing nozzles and achieve optimal efficiency and cost savings in your dispensing process.