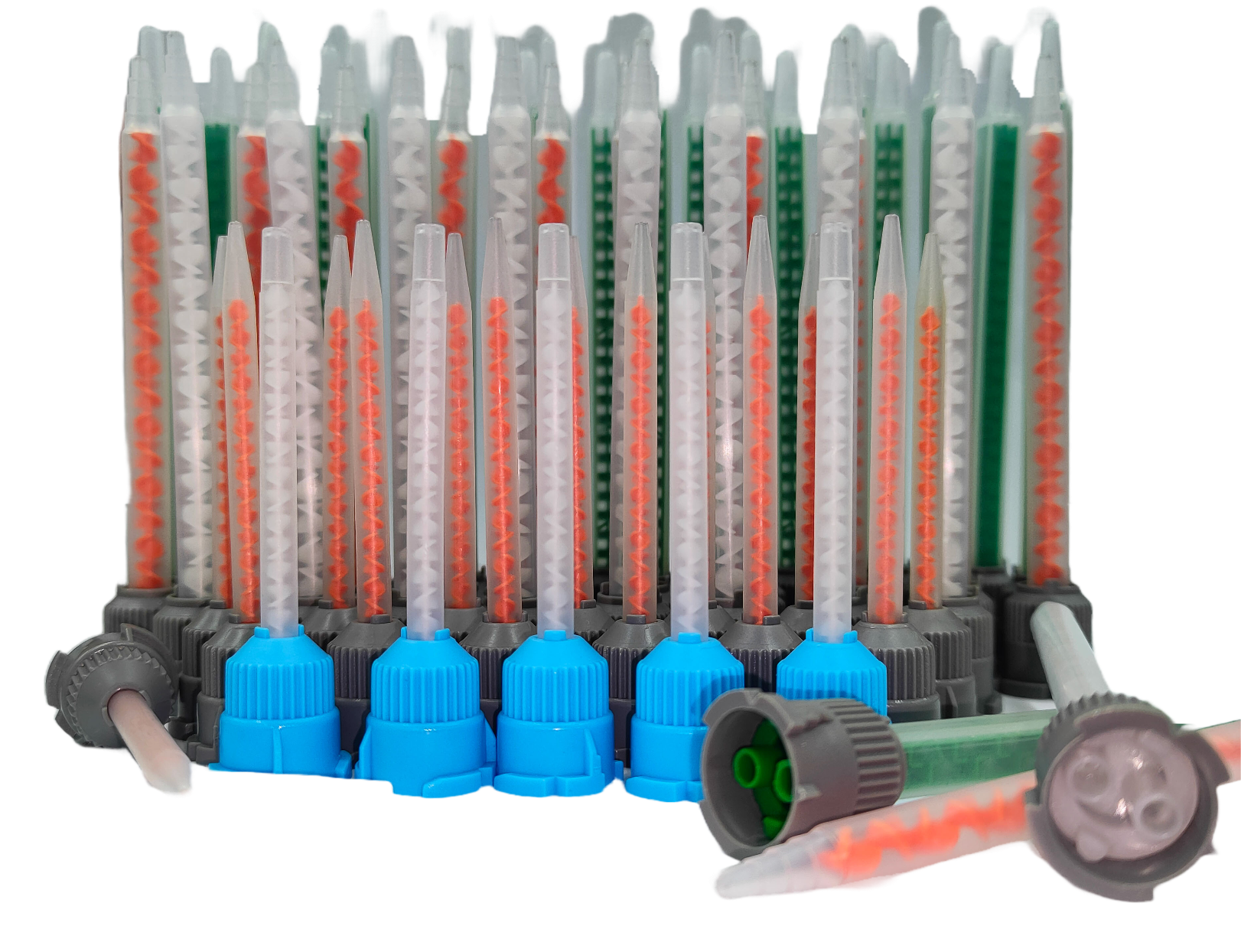

Epoxy mixing nozzles are vital tools in various industries, enabling precise and controlled dispensing of epoxy resins and adhesives. These nozzles consist of several key components that work together to ensure accurate mixing and reliable performance. Understanding the elements of epoxy mixing nozzles is crucial for achieving efficient dispensing and optimal results. Let’s delve into the key components of epoxy mixing nozzles and their importance in various applications.

Mixing Chamber:

At the heart of an epoxy mixing nozzle lies the mixing chamber. This component plays a critical role in blending the two components of the epoxy system into a homogenous mixture. The mixing chamber typically incorporates static mixing elements, such as baffles, fins, or helical elements. These elements facilitate thorough blending by promoting turbulence and intermixing of the resin components as they pass through the nozzle.

Construction Material:

Epoxy mixing nozzles are typically constructed from durable and chemically-resistant materials. High-quality plastics like polypropylene (PP) or polyethylene (PE) are commonly used due to their ability to withstand the corrosive nature of epoxy resins. The chosen construction material ensures the longevity and reliability of the nozzle, even when exposed to harsh chemical environments.

Inner and Outer Diameter:

Epoxy mixing nozzles are available in various sizes with different inner and outer diameters. The inner diameter determines the flow rate of the epoxy components, while the outer diameter ensures compatibility with the dispensing equipment. Selecting the appropriate size and diameter ensures a consistent flow and prevents any blockages or leakage during the dispensing process.

Connection Type:

The connection type of an epoxy mixing nozzle is designed to fit specific dispensing systems. The most common connection options include bayonet-style or threaded connections. This compatibility allows for easy attachment to the cartridge or dispensing gun, ensuring a secure and reliable connection throughout the application.

Mixing Ratio Indicators:

To maintain the correct mixing ratio, some epoxy mixing nozzles incorporate visual indicators, such as color-coded segments or lines. These indicators serve as a guide, ensuring the accurate proportioning of the resin and hardener components. By following the mixing ratio indicators, users can achieve consistent and reliable results, maximizing the performance of the cured epoxy material.

Conclusion

In conclusion, epoxy mixing nozzles consist of several key components that work together to facilitate efficient and accurate dispensing of epoxy resins and adhesives. From the mixing chamber and construction material to the inner and outer diameter, connection type, and mixing ratio indicators, each component plays a crucial role in achieving optimal results. By understanding these elements, users can select the appropriate epoxy mixing nozzle for their application and ensure precise and reliable dispensing, leading to successful epoxy-based projects.