Epoxy mixing nozzles are a common sight in the world of adhesive applications. They are designed to accurately mix and dispense epoxy resins, ensuring a proper ratio of resin and hardener for a strong bond. However, some people may wonder whether epoxy mixing nozzles can be used for other fluids besides epoxy. In this blog post, we’ll explore the versatility of epoxy mixing nozzles and discuss the factors to consider when using them with different types of fluids.

The Basics of Epoxy Mixing Nozzles

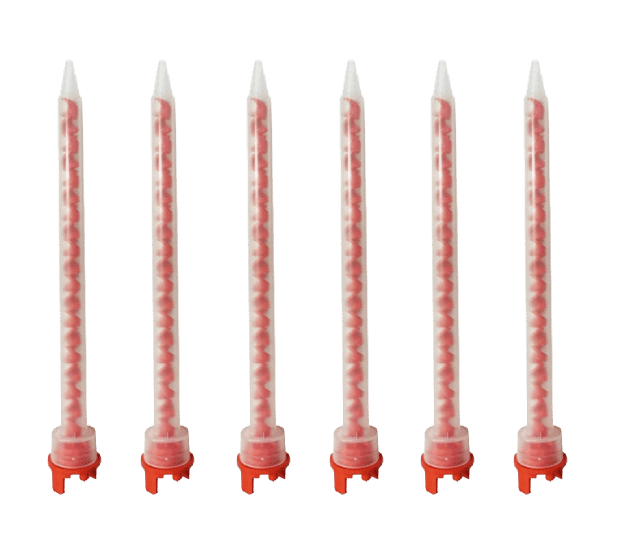

Epoxy mixing nozzles are typically used in a two-component adhesive system. They consist of two channels that carry the epoxy resin and hardener separately, with static mixing elements inside the nozzle. When these two components are forced through the nozzle, they mix thoroughly, ensuring the correct chemical reaction and curing process for the epoxy.

Can Epoxy Mixing Nozzles Be Used for Other Fluids?

The short answer is yes, epoxy mixing nozzles can be used for other fluids, but there are some important considerations to keep in mind.

- Compatibility: The most critical factor when using epoxy mixing nozzles with other fluids is compatibility. The materials used in the nozzle, including the mixing elements, must be chemically compatible with the fluid being dispensed. Some fluids can react with the materials in the nozzle or the adhesive components left in the mixing elements, which may lead to clogging, contamination, or compromised fluid properties.

- Viscosity: Epoxy mixing nozzles are designed to work with materials of specific viscosities. If you’re using a fluid that is significantly more viscous or less viscous than epoxy, the nozzle’s performance may be affected. For very thick fluids, you may need a nozzle with larger channels and mixing elements, while for thinner fluids, the standard nozzle may not work effectively.

- Mixing Efficiency: The design of epoxy mixing nozzles is optimized for the thorough mixing of two components. When using them for single-component fluids, it’s important to assess whether the mixing efficiency is sufficient for the specific application. In some cases, a different type of mixing nozzle or system may be more suitable.

- Cleanliness: If you’re switching between different fluids using the same nozzle, it’s crucial to clean the nozzle thoroughly to prevent contamination and ensure the desired performance of each fluid.

- Flow Rate: Epoxy mixing nozzles are typically designed for a specific flow rate. If you intend to use them with other fluids, make sure the flow rate matches the requirements of your application.

Applications of Epoxy Mixing Nozzles with Other Fluids

While epoxy mixing nozzles are primarily designed for adhesive applications, they can be adapted for other uses. Some common examples include:

- Dispensing sealants and coatings.

- Applying lubricants in machinery.

- Metering and dispensing different chemicals in various industrial processes.

Conclusion

Epoxy mixing nozzles can indeed be used for other fluids, but careful consideration of compatibility, viscosity, mixing efficiency, cleanliness, and flow rate is essential. Adapting these nozzles for different applications can be a cost-effective and efficient solution when the right conditions are met. Always consult with the manufacturer or a specialist to ensure a smooth transition from epoxy to other fluids, and maintain the quality and reliability of your dispensing system.