Fluid dispensing is a critical process in many industries, including automotive, aerospace, electronics, and medical devices. Accurate and consistent dispensing is essential to ensure product quality and reliability. However, achieving the desired dispensing precision can be challenging, especially when working with viscous or reactive fluids. One solution to this challenge is the use of static mixing nozzles, which offer several benefits over other types of mixing methods. In this article, we will explore the benefits of static mixing nozzles in detail and explain how they can help improve efficiency and quality in fluid dispensing applications.

What are Static Mixing Nozzles?

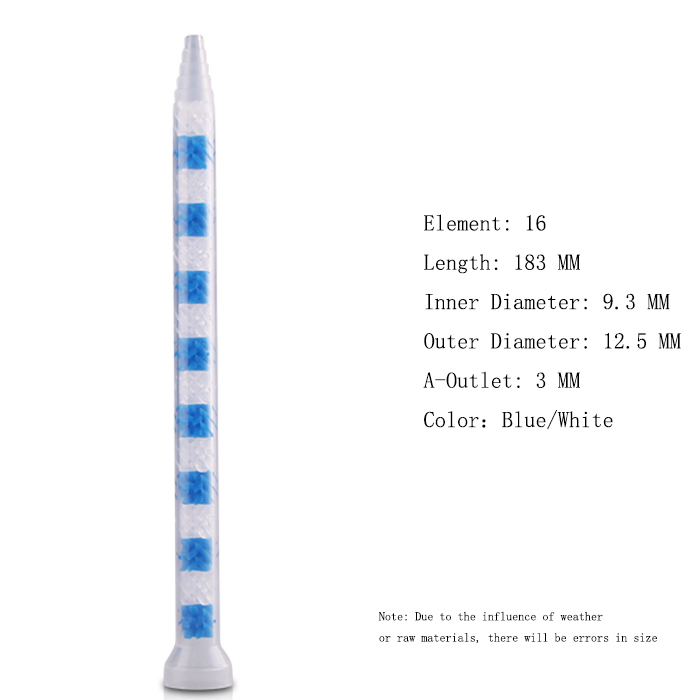

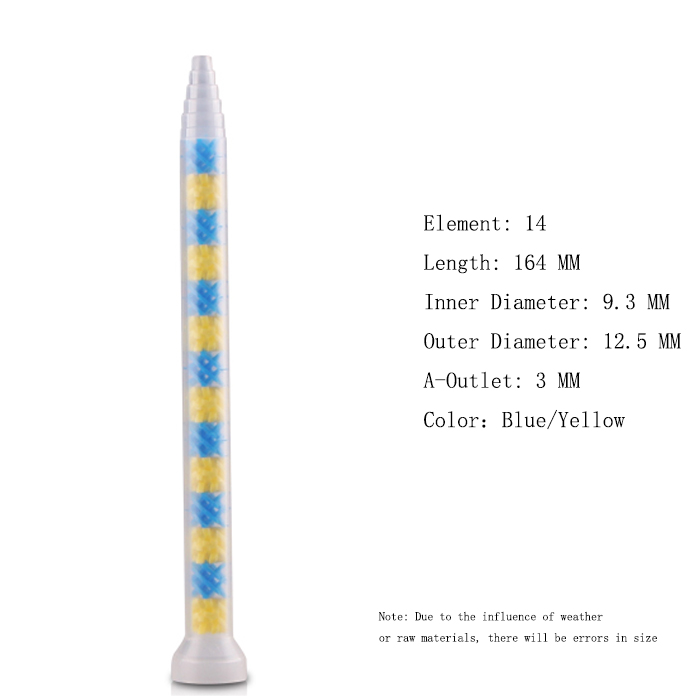

Static mixing nozzles are devices that combine two or more fluids to produce a homogeneous mixture. Unlike dynamic mixers, which rely on impellers or other mechanical mixing elements to blend fluids, static mixers use a series of stationary elements to promote mixing. The design of static mixers varies depending on the application, but most consist of a series of baffles or blades that force the fluids to interact and mix as they flow through the nozzle.

Benefits of Static Mixing Nozzles

-

Improved Mixing Efficiency

One of the primary benefits of static mixing nozzles is their ability to efficiently and consistently mix fluids. Static mixers have a high mixing efficiency, meaning they can achieve a high degree of homogeneity in a short period. This is especially true for fluids with high viscosity or low flow rates, which can be challenging to mix using other methods. Static mixers can also help reduce waste by ensuring that all of the fluid is used and reducing the amount of material that needs to be discarded due to uneven mixing.

-

Enhanced Dispensing Precision

Static mixing nozzles can also improve dispensing precision by providing a uniform mixture of fluids. This is critical in applications where the ratio of the two fluids is critical to achieving the desired properties of the final product. With static mixers, there is no need to worry about variations in mixing due to human error or differences in flow rates. The nozzle ensures that the fluids are thoroughly mixed, resulting in a more consistent and reliable dispensing process.

-

Reduced Labor Costs

Another benefit of static mixing nozzles is that they can help reduce labor costs. Because static mixers are automated, they require less manual labor than other mixing methods. This can result in significant cost savings over time, especially in high-volume production environments. Additionally, static mixers are easy to install and require minimal maintenance, further reducing labor costs associated with upkeep.

-

Versatility

Static mixing nozzles are also highly versatile, capable of mixing a wide range of fluids with varying viscosities and flow rates. This makes them ideal for use in many industries, including automotive, aerospace, electronics, and medical devices. Static mixers can also be customized to meet the specific needs of each application, with different designs and materials available to optimize performance.

-

Eco-Friendly

Static mixing nozzles are also an eco-friendly option for fluid mixing. Because they are highly efficient and require less material to achieve the desired mixing, they can help reduce waste and minimize environmental impact. Additionally, static mixers are often designed to be reusable, further reducing the amount of material that needs to be discarded.

Applications of Static Mixing Nozzles

Static mixing nozzles are used in a wide range of applications, including:

-

Adhesive dispensing

Adhesive dispensing is one of the most common applications of static mixing nozzles. In this process, two or more components are combined to form an adhesive that is then applied to a substrate. Static mixers are ideal for adhesive dispensing because they can provide a uniform mixture of the adhesive, ensuring a strong and reliable bond between the substrate and the adhesive.

-

Coating and painting

Coating and painting is another application where static mixing nozzles are commonly used. In this process, two or more fluids are mixed to form a coating or paint that is then applied to a surface. Static mixers can ensure a uniform and consistent coating or paint, resulting in a high-quality finish.

-

Chemical processing

Chemical processing is another area where static mixing nozzles are widely used. In this process, two or more chemicals are combined to form a reaction. Static mixers can ensure a thorough mixing of the chemicals, resulting in a more efficient and effective reaction.

-

Food and beverage processing

In the food and beverage industry, static mixing nozzles are used to ensure the quality and safety of products. For example, in the production of beverages, static mixers can ensure that the correct amount of flavoring and coloring is added to the drink, resulting in a consistent and high-quality product.

-

Medical devices

In the medical device industry, static mixing nozzles are used to ensure the accuracy and consistency of fluid dispensing. For example, in the production of medical adhesives or sealants, static mixers can ensure a uniform and reliable mixture, resulting in a more effective product.

-

Oil and gas processing

In the oil and gas industry, static mixing nozzles are used to ensure the efficient and effective processing of fluids. For example, in the processing of crude oil, static mixers can ensure a thorough mixing of chemicals, resulting in a more efficient refining process.

-

Water treatment

In water treatment, static mixing nozzles are used to ensure the thorough mixing of chemicals, resulting in a more effective treatment process. For example, in the treatment of wastewater, static mixers can ensure that the correct amount of chemicals is added to the water, resulting in a more efficient and effective treatment process.

In each of these applications, static mixing nozzles offer significant benefits over other types of mixing methods, including improved mixing efficiency, enhanced dispensing precision, reduced labor costs, versatility, and eco-friendliness.

Conclusion

In summary, static mixing nozzles can help you dispense fluids quickly and precisely. If you are looking to improve the efficiency and quality of your fluid dispensing applications, static mixing nozzles may be the solution you need.