In the world of adhesive application, precision and efficiency are paramount. Traditional methods of mixing epoxy components often involve manual labor and can lead to inconsistencies in the adhesive’s properties. Enter self-mixing epoxy nozzles, a game-changer in the field of adhesive dispensing.

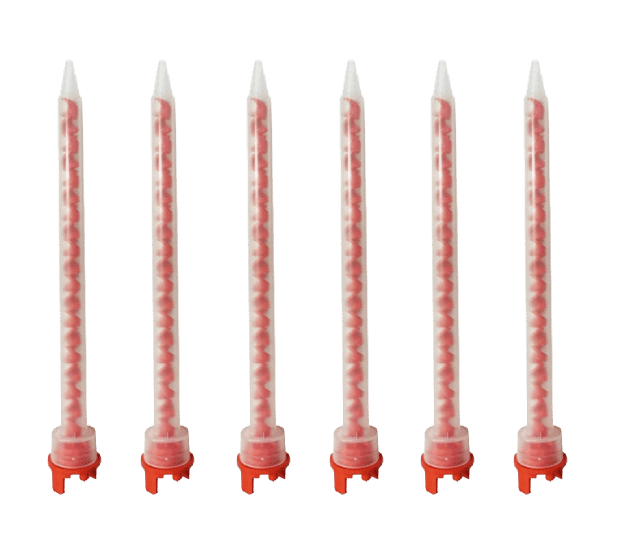

Self-mixing epoxy nozzles are specially designed to blend epoxy resin and hardener seamlessly as they are dispensed. This innovative technology eliminates the need for manual mixing, ensuring a consistent and homogenous mixture every time. The result? Improved adhesive performance and a more efficient application process.

In this blog series, we will delve into the world of self-mixing epoxy nozzles, exploring their benefits, applications, and best practices for use. Join us as we uncover the secrets behind this revolutionary technology and discover how it is transforming the way we apply adhesives.

Benefits of Using Self-Mixing Epoxy Nozzles

Self-mixing epoxy nozzles offer a range of benefits that make them a superior choice for adhesive dispensing. Here are some key advantages:

Consistent Mixing: Self-mixing nozzles ensure thorough and consistent blending of epoxy components, eliminating the risk of improper mixing that can lead to adhesive failure.

Time and Labor Savings: By automating the mixing process, self-mixing nozzles save time and reduce the need for manual labor, making adhesive application more efficient.

Reduced Waste: With precise mixing ratios and on-demand mixing, self-mixing nozzles help reduce waste by ensuring that only the required amount of adhesive is dispensed.

Improved Adhesive Performance: Properly mixed adhesives exhibit enhanced performance characteristics, such as increased bond strength and durability.

Versatility: Self-mixing epoxy nozzles can be used in a wide range of applications, from industrial bonding to DIY projects, making them a versatile choice for adhesive dispensing.

Cost-Effectiveness: While the initial cost of self-mixing nozzles may be higher than traditional methods, the long-term savings in time, labor, and adhesive usage can make them a cost-effective solution.

Ease of Use: Self-mixing nozzles are easy to use, requiring minimal training for operators to achieve optimal results.

Applications of Self-Mixing Epoxy Nozzles

Self-mixing epoxy nozzles are versatile tools with a wide range of applications across various industries. Here are some common uses:

Construction and Building: Self-mixing epoxy nozzles are used in construction for bonding materials like concrete, metal, and wood. They are also used in sealing applications for windows, doors, and joints.

Automotive: In the automotive industry, self-mixing epoxy nozzles are used for bonding parts, such as plastic trim, mirrors, and panels. They are also used in repair applications, such as fixing cracks in engine components.

Electronics: Self-mixing epoxy nozzles are used in electronics manufacturing for bonding components, such as circuit boards and sensors. They are also used for potting and encapsulation to protect electronic components from environmental factors.

Aerospace: In the aerospace industry, self-mixing epoxy nozzles are used for bonding and repair applications on aircraft components. They are also used in the manufacture of composite materials used in aircraft construction.

Marine: In the marine industry, self-mixing epoxy nozzles are used for bonding and repair applications on boats and ships. They are also used for sealing applications to prevent water ingress.

DIY and Hobbyist: Self-mixing epoxy nozzles are popular among DIY enthusiasts and hobbyists for various projects, such as woodworking, jewelry making, and model building.

Medical: In the medical industry, self-mixing epoxy nozzles are used for bonding and sealing applications in medical devices and equipment.

General Manufacturing: Self-mixing epoxy nozzles are used in general manufacturing for bonding and sealing applications in various industries, such as appliances, furniture, and sporting goods.

Features to Look for in Self-Mixing Epoxy Nozzles

When choosing a self-mixing epoxy nozzle for your adhesive dispensing needs, it’s essential to consider several key features to ensure optimal performance. Here are some features to look for:

Mixing Ratio: The mixing ratio of the nozzle should match the requirements of your epoxy adhesive. Ensure that the nozzle provides a consistent and accurate mixing ratio to achieve the desired adhesive properties.

Mixing Element Design: The design of the mixing element inside the nozzle plays a crucial role in ensuring thorough mixing of the epoxy components. Look for a nozzle with a well-designed mixing element that can effectively blend the components.

Compatibility: Ensure that the self-mixing epoxy nozzle is compatible with the specific epoxy adhesive you are using. Some nozzles may be designed for specific types of adhesives, so check the compatibility before purchasing.

Size and Shape: Consider the size and shape of the nozzle, as it can affect the ease of use and the application of the adhesive. Choose a size and shape that are suitable for your application requirements.

Material: The material of the self-mixing epoxy nozzle should be compatible with the adhesive and ensure durability and longevity. Common materials include polypropylene and stainless steel.

Ease of Cleaning: Choose a self-mixing epoxy nozzle that is easy to clean to maintain its performance and prevent cross-contamination between different adhesive types.

Compatibility with Dispensing Equipment: Ensure that the self-mixing epoxy nozzle is compatible with your dispensing equipment, such as syringe barrels or dispensing guns, to ensure proper operation.

Cost-Effectiveness: Consider the cost of the self-mixing epoxy nozzle in relation to its features and performance to ensure that you are getting the best value for your investment.

How to Use Self-Mixing Epoxy Nozzles: A Step-by-Step Guide

Self-mixing epoxy nozzles are easy to use, but proper technique is essential to ensure optimal adhesive performance. Follow these steps for successful application:

Prepare the Epoxy: Ensure that the epoxy resin and hardener are properly prepared according to the manufacturer’s instructions. Make sure both components are at the correct temperature and viscosity for dispensing.

Attach the Nozzle: Attach the self-mixing epoxy nozzle to your dispensing equipment, such as a syringe barrel or dispensing gun, ensuring a secure fit.

Prime the Nozzle: Before dispensing epoxy, prime the nozzle by dispensing a small amount of epoxy to ensure that the mixing elements are properly coated.

Dispense the Epoxy: Squeeze the dispensing equipment’s trigger or plunger to begin dispensing the epoxy. Ensure a steady and consistent flow to achieve an even mixture.

Apply the Adhesive: Apply the mixed epoxy to the substrate or surface that you are bonding or sealing. Work quickly but carefully to ensure that the adhesive does not cure before application.

Allow the Adhesive to Cure: Once the adhesive is applied, allow it to cure according to the manufacturer’s instructions. Avoid disturbing the adhesive during curing to ensure a strong bond.

Clean the Nozzle: After use, clean the self-mixing epoxy nozzle thoroughly to remove any remaining epoxy and prevent clogging. Use an appropriate solvent or cleaning solution recommended by the nozzle manufacturer.

Store the Nozzle Properly: Store the self-mixing epoxy nozzle in a clean and dry place to prevent contamination and ensure that it is ready for future use.

Maintenance and Care of Self-Mixing Epoxy Nozzles: Tips for Longevity

Proper maintenance and care of self-mixing epoxy nozzles are essential to ensure their longevity and optimal performance. Here are some tips to keep your nozzles in top condition:

Clean Regularly: After each use, clean the self-mixing epoxy nozzle thoroughly to remove any remaining adhesive. Use a suitable solvent or cleaning solution recommended by the nozzle manufacturer.

Inspect for Damage: Regularly inspect the self-mixing epoxy nozzle for any signs of damage, such as cracks, wear, or clogs. Replace the nozzle if any damage is found to prevent issues during application.

Store Properly: Store the self-mixing epoxy nozzle in a clean and dry place when not in use. Avoid exposing the nozzle to extreme temperatures or harsh chemicals that could damage the material.

Use Correctly: Follow the manufacturer’s instructions for using the self-mixing epoxy nozzle, including proper attachment to dispensing equipment and correct application techniques.

Replace When Necessary: Replace the self-mixing epoxy nozzle regularly, as recommended by the manufacturer or when signs of wear or damage are present. Using a worn or damaged nozzle can affect the quality of the adhesive application.

Avoid Cross-Contamination: Use separate self-mixing epoxy nozzles for different types of adhesives to avoid cross-contamination. This helps maintain the integrity of the adhesive properties.

Keep Mixing Elements Clean: Ensure that the mixing elements inside the self-mixing epoxy nozzle are kept clean and free from hardened adhesive. Use a small brush or cleaning tool to remove any buildup.