Epoxy mixing nozzles are an essential tool for many applications, particularly in the construction, automotive, manufacturing, and dispensing industries. They are designed to mix and dispense two-part epoxies accurately, consistently, and efficiently. In this blog, we will explore what epoxy mixing nozzles are, how to choose the right one, how to use them, tips for maximizing their effectiveness, and a conclusion highlighting their advantages.

What is Epoxy Mixing Nozzle?

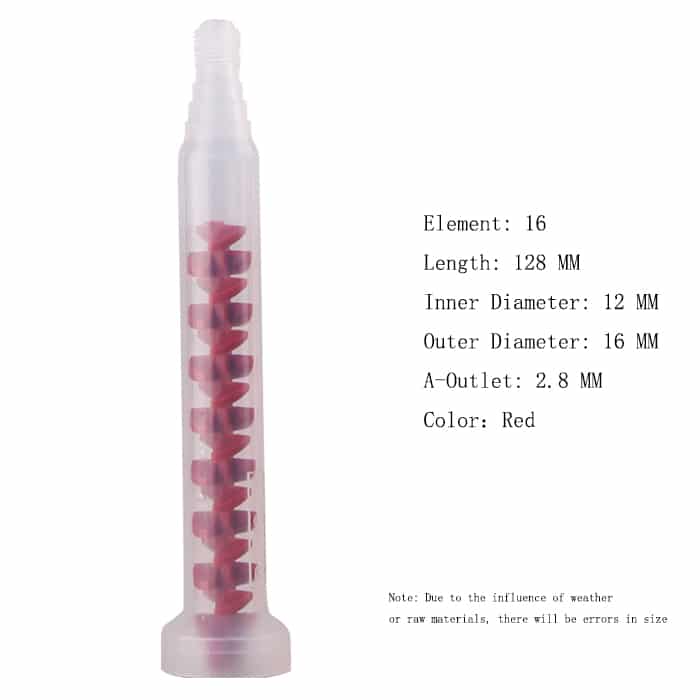

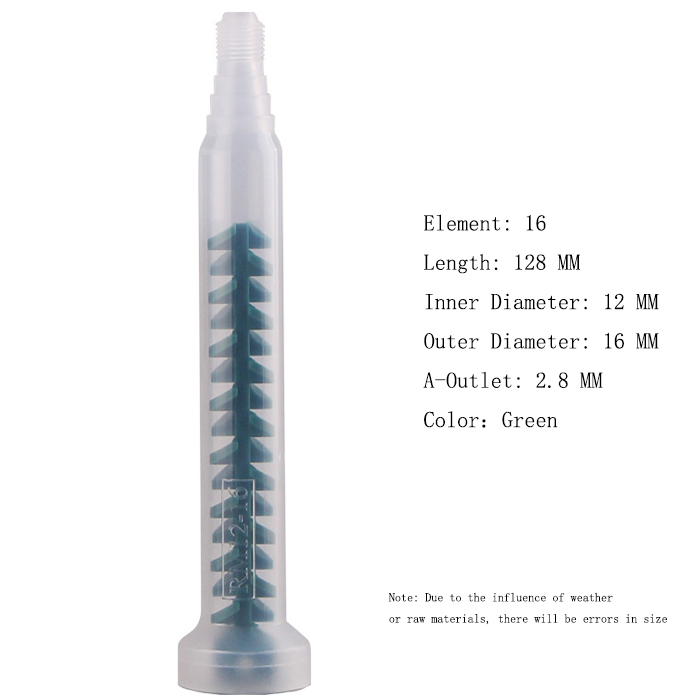

Epoxy mixing nozzles are devices that are used to mix and dispense two-part epoxies. They are made up of two parts, an A-side and a B-side, which are mixed together in the nozzle to create a homogenous mixture. The nozzle is designed to ensure that the two parts are mixed thoroughly and evenly, providing a strong and reliable bond. The design of the nozzle is such that it incorporates static mixing elements, which are responsible for ensuring that the two components mix together correctly.

How to Choose the Right Epoxy Mixing Nozzle?

Choosing the right epoxy mixing nozzle depends on several factors, including the type of epoxy being used, the application, and the user’s requirements. Some of the factors to consider when choosing an epoxy mixing nozzle are:

-

Mixing Ratio:

Epoxy mixing nozzles come in different mixing ratios, typically ranging from 1:1 to 10:1. It is important to choose a nozzle with the correct mixing ratio to ensure that the two components are mixed accurately.

-

Size:

Epoxy mixing nozzles come in different sizes, depending on the application. The size of the nozzle should be chosen based on the amount of adhesive or sealant that needs to be dispensed.

-

Material:

The material used to make the epoxy mixing nozzle is also an important factor to consider. The material should be compatible with the epoxy being used to ensure that it does not react with the material.

-

Application:

The application for which the epoxy mixing nozzle is being used is also important. Some applications may require a specific type of nozzle, such as a static mixing nozzle or a dynamic mixing nozzle.

How to Use Epoxy Mixing Nozzle

Using an epoxy mixing nozzle is relatively easy. Here is a step-by-step guide to using an epoxy mixing nozzle:

- Attach the nozzle to the dual-component adhesive cartridge.

- Remove the cap from the nozzle.

- Dispense a small amount of the adhesive or sealant to ensure that both components are flowing evenly.

- Apply the adhesive or sealant to the surface to be bonded.

- Dispose of the used nozzle and cap after use.

Tips

Here are some tips to maximize the effectiveness of epoxy mixing nozzles:

- Always choose the right size and mixing ratio of the nozzle for the application.

- Use a clean and dry surface for bonding.

- Store the adhesive or sealant and nozzle in a cool and dry place.

- Always dispense a small amount of the adhesive or sealant before applying it to the surface.

- Use the adhesive or sealant within the recommended pot life to ensure optimal bonding.

- Dispose of used nozzles and cartridges in an environmentally friendly manner.

In summary, epoxy mixing nozzles are an essential tool for anyone who needs to bond two components together. They come in various sizes and mixing ratios to suit different applications, and their design ensures that the two parts mix together thoroughly and evenly. By choosing the right nozzle, following proper usage techniques, and storing them correctly, users can achieve excellent results and enjoy the benefits of this versatile tool.