When it comes to applying coatings and other materials in the construction industry, achieving a consistent and high-quality finish is critical. This is where the X-Grid mixing nozzle comes in – a specialized tool that has revolutionized the way two-component materials are mixed and applied.

What is the X-Grid Mixing Nozzle?

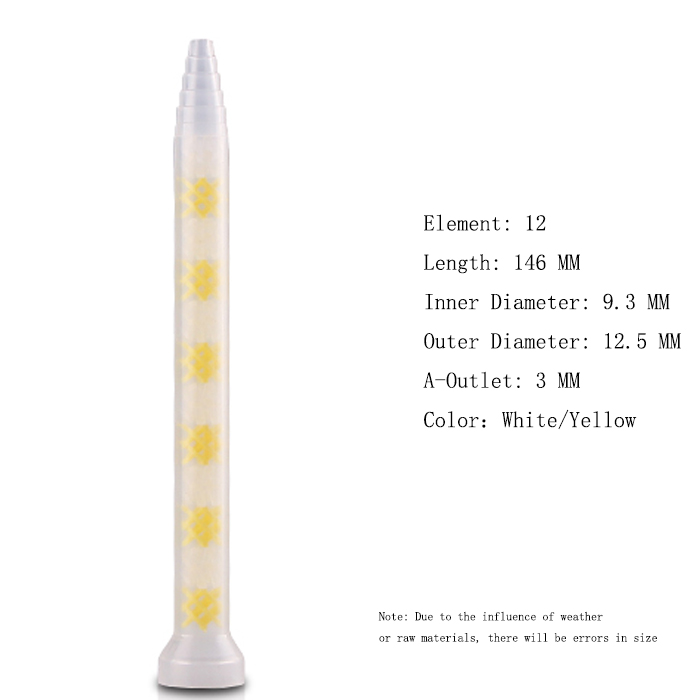

The X-Grid mixing nozzle is a specialized nozzle designed for use with plural-component spray equipment, which is commonly used in the coatings and construction industries. The nozzle is designed to mix and atomize two-component materials at the point of application, resulting in a consistent and homogenous mixture that can be applied with precision and accuracy.

The X-Grid nozzle features a unique grid pattern that ensures thorough mixing of the two-component materials. The nozzle is designed to work with a variety of different materials, including low and high viscosity coatings, and can be used with both airless and air-assisted spray equipment.

How Does the X-Grid Mixing Nozzle Work?

The X-Grid mixing nozzle works by combining two-component materials at the point of application. The nozzle has two separate chambers that are designed to hold each component of the material. As the material passes through the nozzle, it is forced through the X-Grid, which mixes the two components together thoroughly.

The grid pattern of the X-Grid ensures that the two components are mixed completely and evenly, resulting in a homogenous mixture that can be applied with precision and accuracy. This helps to ensure a consistent finish, without the need for costly rework or touch-ups.

Benefits of the X-Grid Mixing Nozzle

The X-Grid mixing nozzle offers a range of benefits for professionals in the coatings and construction industries. Some of the key benefits include:

-

Improved Efficiency

By mixing the two-component materials at the point of application, the X-Grid nozzle helps to reduce material waste and improve efficiency. This is because the mixture is fresh and consistent, reducing the need for costly rework and touch-ups. Additionally, the nozzle can be easily cleaned and reused for multiple applications, helping to minimize downtime and maximize productivity.

-

Consistent and High-Quality Finishes

One of the main benefits of the X-Grid mixing nozzle is that it helps to ensure consistent and high-quality finishes. The nozzle’s unique grid pattern ensures that the two-component materials are mixed thoroughly and evenly, resulting in a homogenous mixture that can be applied with precision and accuracy. This helps to minimize the risk of defects and inconsistencies in the finish.

-

Versatile

The X-Grid mixing nozzle is designed to work with a variety of different materials, including low and high viscosity coatings. It can also be used with both airless and air-assisted spray equipment, making it a versatile tool for professionals in the coatings and construction industries.

-

Reduced Material Waste

The X-Grid mixing nozzle helps to reduce material waste by ensuring that the two-component materials are mixed thoroughly and evenly. This helps to minimize the need for rework and touch-ups, reducing the amount of material that is wasted during the application process.

-

Improved Safety

The X-Grid mixing nozzle can improve safety in the workplace by reducing the need for manual mixing of two-component materials. This reduces the risk of exposure to hazardous chemicals and helps to ensure that the mixture is consistent and homogenous.

Tips for Using the X-Grid Mixing Nozzle

To get the most out of the X-Grid mixing nozzle, there are a few tips that professionals in the coatings and construction industries should keep in mind:

-

Follow Manufacturer Instructions

It’s essential to follow the manufacturer’s instructions when using the X-Grid mixing nozzle. This ensures that the nozzle is used correctly and that the mixture is consistent and homogenous.

-

Clean the Nozzle Properly

After each use, it’s important to clean the X-Grid mixing nozzle thoroughly to prevent buildup and ensure optimal performance. Follow the manufacturer’s instructions for cleaning the nozzle, and make sure to use the appropriate cleaning solution for the materials being used.

-

Check for Wear and Tear

Regularly inspect the X-Grid mixing nozzle for signs of wear and tear, such as cracks or damage to the grid pattern. If any damage is detected, replace the nozzle immediately to ensure consistent and high-quality finishes.

-

Use the Right Equipment

The X-Grid mixing nozzle is designed to work with plural-component spray equipment, so it’s important to use the right equipment for the job. Using the wrong equipment can result in suboptimal performance and potentially unsafe conditions.

Conclusion

The X-Grid mixing nozzle is a game-changing tool for professionals in the coatings and construction industries. It offers a range of benefits, including improved efficiency, consistent and high-quality finishes, versatility, reduced material waste, and improved safety. By following the manufacturer’s instructions and using the right equipment, professionals can get the most out of the X-Grid mixing nozzle and achieve optimal results in their work.