Mixer nozzles are essential components in dispensing two-part adhesives. They play a crucial role in ensuring that the adhesive components are mixed thoroughly before being dispensed. Without a properly functioning mixer nozzle, the adhesive may not cure correctly or may have reduced strength.

In this blog post, we will discuss mixer nozzles for two-part adhesive cartridges in detail. We will cover the types of mixer nozzles, their benefits, and how to choose the right mixer nozzle for your application.

Types of Mixer Nozzles

There are two main types of mixer nozzles: static mixer nozzles and dynamic mixer nozzles. Each type has its benefits and limitations, and the choice depends on the adhesive being used and the dispensing application.

Static Mixer Nozzles

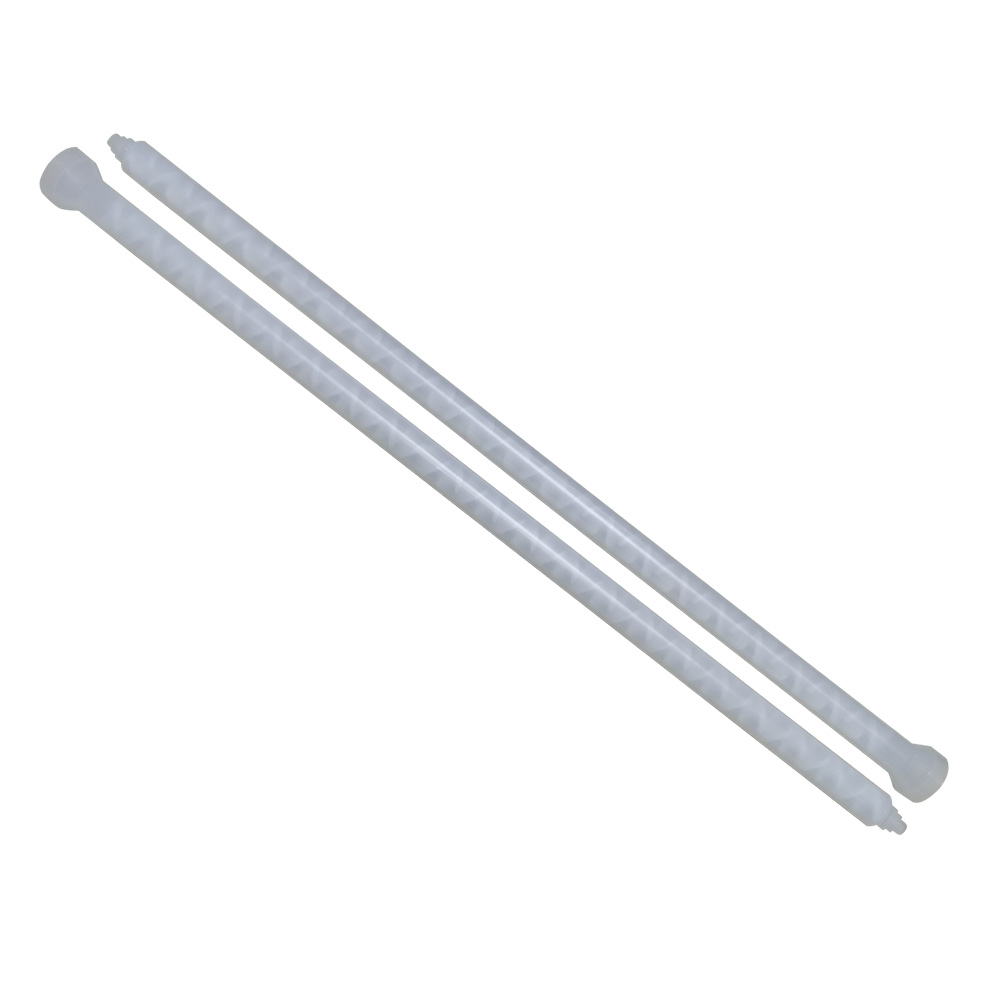

Static mixer nozzles consist of a series of fixed mixing elements that are placed inside a nozzle housing. These elements are designed to mix the two adhesive components as they pass through the nozzle.

Static mixer nozzles are ideal for low to medium viscosity adhesives and are available in various sizes and configurations to suit different applications. They are easy to use and require minimal setup time.

One of the key benefits of static mixer nozzles is that they are disposable, which eliminates the need for cleaning and reduces the risk of contamination. They are also cost-effective and widely available.

However, static mixer nozzles are not suitable for high viscosity adhesives or those with a short pot life. The fixed mixing elements can become clogged if the adhesive is too thick, which can affect the mixing performance.

Dynamic Mixer Nozzles

Dynamic mixer nozzles use a rotating mixing element to mix the adhesive components. The mixing element is powered by a dispensing gun and rotates at high speeds to ensure thorough mixing.

Dynamic mixer nozzles are ideal for high viscosity adhesives or those with a short pot life. They provide better mixing performance than static mixer nozzles and can be used for a wide range of applications.

One of the benefits of dynamic mixer nozzles is that they can be reused, which reduces waste and makes them more cost-effective in the long run. They also provide better mixing performance than static mixer nozzles.

However, dynamic mixer nozzles require more setup time and are not as widely available as static mixer nozzles. They can also be more expensive than static mixer nozzles.

Benefits of Using Mixer Nozzles

Mixer nozzles offer several benefits when dispensing two-part adhesives, including:

-

Thorough mixing:

Mixer nozzles ensure that the two adhesive components are mixed thoroughly, which is essential for proper curing and bonding.

-

Consistency:

Mixer nozzles provide consistent mixing performance, which reduces the risk of errors and improves the quality of the final product.

-

Time-saving:

Mixer nozzles can save time compared to manual mixing, which is especially important in high-volume applications.

-

Reduced waste:

Mixer nozzles can reduce waste by ensuring that the correct amount of adhesive is dispensed and by eliminating the need for manual mixing and cleaning.

Choosing the Right Mixer Nozzle

Choosing the right mixer nozzle depends on several factors, including:

-

Adhesive viscosity:

The viscosity of the adhesive will determine whether a static or dynamic mixer nozzle is required.

-

Pot life:

The pot life of the adhesive will determine the mixing speed required. Adhesives with a short pot life require a faster mixing speed, which can be achieved with a dynamic mixer nozzle.

-

Dispensing application:

The dispensing application will determine the size and configuration of the mixer nozzle required. For example, a narrow or angled mixer nozzle may be required for hard-to-reach areas.

-

Cost:

The cost of the mixer nozzle should also be considered, as well as the cost of any additional equipment required, such as a dispensing gun.

When choosing a mixer nozzle, it is important to consult the adhesive manufacturer’s recommendations and to ensure that the mixer nozzle is compatible with the adhesive being used.

Conclusion

Mixing nozzles are a very useful tool that you can use to easily get adhesives fully mixed. If you have a large demand, we recommend you to contact a professional mixing nozzle manufacturer to get a stable supply and the best price.