Epoxy mixing nozzles are commonly used in a variety of applications, such as construction, automotive, and aerospace industries, where the adhesive properties of epoxy are essential. However, there are situations where epoxy mixing nozzles may not be the most suitable option for adhesive applications, and other adhesives may be used instead. In this blog post, we will explore the properties of epoxy mixing nozzles and other adhesives and answer the question, “Can epoxy mixing nozzles be used with other adhesives?”

The answer is YES, but only cyanoacrylate adhesives should not be used in static mixing nozzles.

Epoxy mixing nozzles

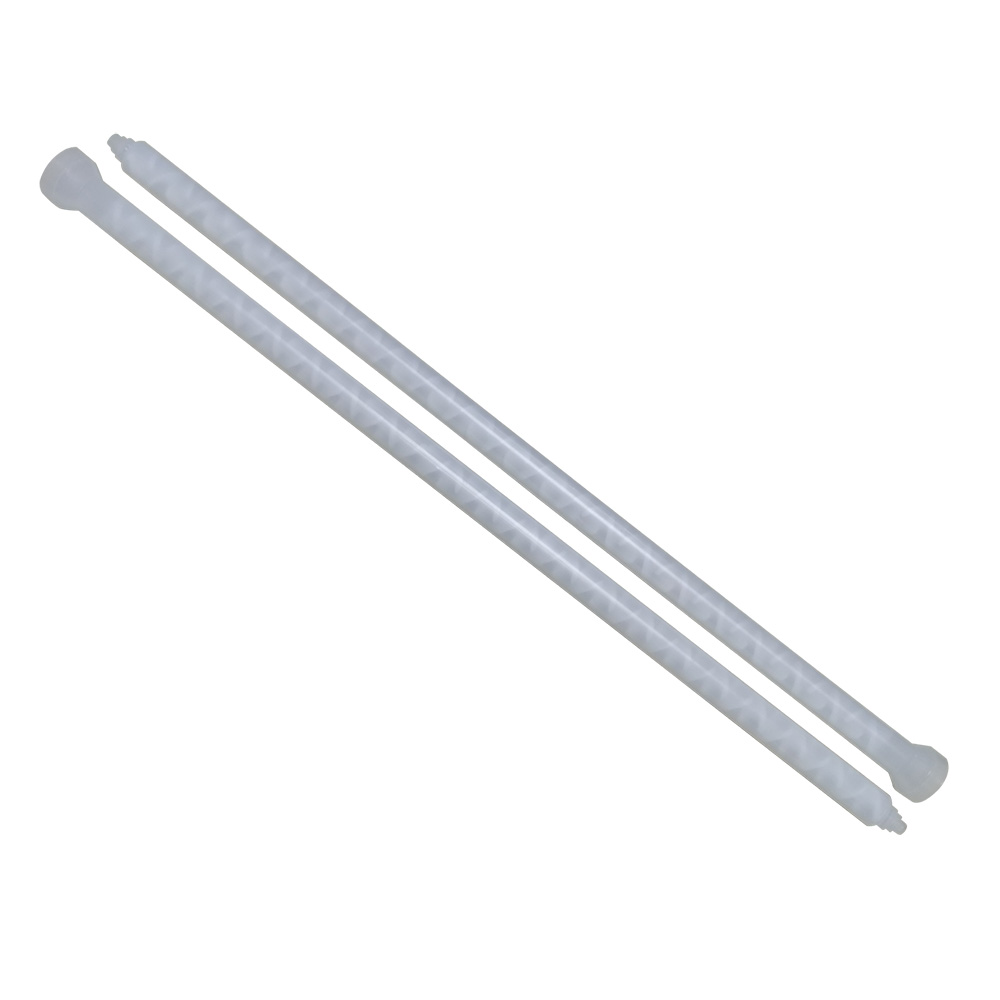

First, let’s understand what epoxy mixing nozzles are and how they work. Epoxy mixing nozzles are typically used to mix and dispense two-part epoxy adhesives. These adhesives consist of a resin and a hardener, which are mixed together to form a strong, durable bond. Epoxy mixing nozzles are designed to facilitate the mixing process by combining the resin and hardener as they are dispensed, resulting in a uniform mixture.

Epoxy mixing nozzles are available in various sizes and configurations, depending on the specific application. Some nozzles are disposable, while others can be cleaned and reused. The most common type of epoxy mixing nozzle is the static mixer, which consists of a series of small mixing elements that are mounted within a plastic housing. As the two-part adhesive is forced through the nozzle, it is forced through the mixing elements, which create a uniform mixture.

Different types of adhesives

Now, let’s discuss other adhesives that can be used instead of epoxy. There are many types of adhesives available, each with their own unique properties and characteristics. Some of the most commonly used adhesives include:

-

Cyanoacrylate adhesives:

Also known as superglue, cyanoacrylate adhesives are fast-setting and create a strong, durable bond. They are often used in small-scale applications, such as jewelry making, electronics assembly, and model building.

-

Acrylic adhesives:

Acrylic adhesives are known for their high strength and resistance to temperature, moisture, and chemicals. They are commonly used in the automotive and aerospace industries, as well as for bonding plastics and metals.

-

Polyurethane adhesives:

Polyurethane adhesives are flexible and have a high resistance to impact and vibration. They are often used in the construction industry for bonding wood, metal, and plastics.

-

Silicone adhesives:

Silicone adhesives are flexible and have excellent resistance to temperature and weathering. They are commonly used for sealing and bonding applications in the automotive, electronics, and construction industries.

-

Epoxy adhesives:

Epoxy adhesives are known for their high strength and durability. They are commonly used in the construction, automotive, and aerospace industries, as well as for bonding metals, plastics, and composites.

Tips

While each of these adhesives has its own unique properties and characteristics, they can generally be used with a wide range of mixing nozzles. However, it is important to note that not all adhesives are compatible with all types of nozzles. For example, cyanoacrylate adhesives should not be used with static mixers, as the high shear forces can cause the adhesive to cure too quickly, resulting in a weak bond.

When choosing a mixing nozzle for a particular adhesive, it is important to consider factors such as viscosity, cure time, and temperature resistance. Some adhesives require a larger or smaller diameter nozzle to achieve the desired flow rate, while others may require a specific type of nozzle to ensure proper mixing.

Conclusion

In conclusion, while epoxy mixing nozzles are specifically designed for use with two-part epoxy adhesives, many other types of adhesives can also be used with a variety of mixing nozzles. When selecting a mixing nozzle for a particular adhesive, it is important to consider the properties of both the adhesive and the nozzle to ensure a strong, durable bond.

In addition, it is important to follow the manufacturer’s instructions for both the adhesive and the mixing nozzle to ensure proper use and to achieve the desired results. Some adhesives may require a specific mixing ratio or cure time, while others may require a certain temperature range for proper curing.

It is also worth noting that in some cases, it may be necessary to use multiple mixing nozzles for a single application, depending on the complexity of the project and the adhesive being used. This may require changing the nozzle between applications, which can be time-consuming and may require additional equipment.